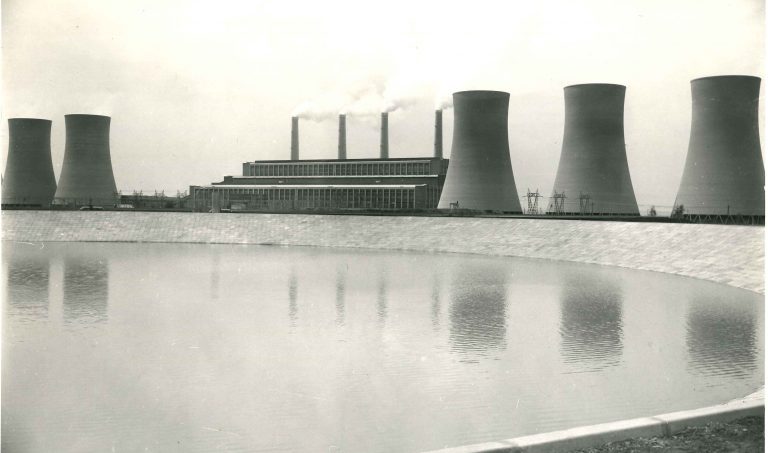

Taaibos Power Station

Taaibos and Highveld power stations each had a capacity of 480MV supplied by 8 turbo generators of 60MW. They were to be the largest and most up-to-date power stations in the ESCOM system at that time. They were intended to be the last power stations in the Vereeniging area because of the limited availability of coal.

The two power stations, Taaibos and Highveld, are situated 0.8 kilometres apart in the Northern Orange Free State, approximately 32 kilometers south of Vereeniging. They formed part of the Rand and OFS Undertaking of the Electricity Supply Commission (ESCOM).

SUPPLY AREA

The original licence for the Rand and OFS Undertaking supply area consisted of a narrow strip on either side of the Witwatersrand extending from Nigel to Randfontein. It also included an area of approximately 5km radius around Heidelberg, and a small area around Vereeniging.

By 1947, the Rand and OFS Undertaking supplied an area of about 103 600 square kilometres and included 4 major gold mining areas, i.e. Witwatersrand, the far West Rand, Klerksdorp and the Orange Free State. The boundaries of the supply area were that of Thabazimbi in the north, Mafeking (Mafikeng today) in the west, Winburg in the south and Witbank in the east.

By 1975 the Rand and OFS Undertaking was extended to 261 000 square kilometres. It was extended to cover a further 250 000 square kilometres by 1979, with areas ranging from the Zimbabwe (then Southern Rhodesia) border in the North, to the Lesotho border in the south, and from Standerton in the east to the Botswana border in the west.

In 1983, this changed when ESCOM decided to amalgamate the separate undertakings into a national grid system. This became a reality in 1984.

STAFF

By 1963, when both Taaibos and Highveld were running at full capacity there were 916 people working at the two stations. ESCOM employed 160 white employees and 300 black employees at Taaibos. At Highveld 156 white employees and 300 black employees were employed.

FACILITIES

At the time that the two stations were being constructed all residents were subjected to ethnic segregation according to the law of the country

The white employees were housed in two villages – one for each power station. They shared recreational facilities, which included a recreation centre, swimming pool, and sports fields (rugby, football and tennis). The residents of Taaibos and Highveld villages developed a strong sense of community. Competitiveness between the two villages emerged in social events and on the sports field.

The recreation club included an alcohol-free canteen, an amateur dramatic society, weekly film shows, a library and badminton and an active Cub and Scout group. The province established a satellite library. Books arrived on a rotational basis from the Kroonstad and Bloemfontein main libraries.

Accommodation for black employees was arranged so that those from the same tribe were grouped together. Whenever possible, those performing similar work were accommodated together. The black housing compounds were built predominantly for single men, although some included quarters for those who were married.

The two stations were totally self-sufficient providing accommodation for employees – single dwelling units, boarding houses and single quarters, a sewage plant and a potable water purification system. The community also had its own horticultural nursery, a convenience store, medical and dental facilities and a post office. The post office was registered as the Kragbron Post Office, which later became the collective name of the two power stations. The province later built a dual medium primary school for the children of residents of the two stations. The power station managers were responsible for the running of the villages.

TECHNICAL DETAILS

- Total station electrical capacity – 480 000kW

- Total boiler capacity – 4 640 000lb/hour

- Steam consumption per kWh generated – 9.3lb

- Approximate calorific value of coal – 8 750 BT

- U/lb

- Oveerall thermal efficiency on units sent out – 26.0%

- Heat rate on units sent out – 13 110 BTU/kWh

- Coal consumption per unit sent out – 1.498lb

BOILER HOUSE

Eight Babcock and Wilcox pulverized-fuel boilers, bi-drum with pendant superheaters and tangent tube furnaces.

- Continuous rating – 580 000lb/hour

- Outlet pressure – 530lb/sq.in

- Outlet temperature – 825° F

Four coal pulverizing mills per boiler, one as a standby, each driven 130hp motor. Capacities of each mill 14 tons per hour.

- Boiler feed pumps: Capacity 700 000 lb/hour each

- Length of boiler house – 654 feet

- Driven by 1 290hp motor. Standby steam feed pumpt to dams at the east of the station

- Height of boiler house – 158 feet

- Ash plant – Babcock & Wilcox hydro-jet system

- Each boiler produces approximately 8 tons per hours

- Ash pumped to dams to the east of station

COAL PLANT

Coal was obtained from the Clydesdale Colliery, and delivered by overland belt conveyer 5 600 feet long to station coal staiths, with a storage capacity of 24 000 tons.

- Capacity of conveyor – 650 tons/hour

- Belt – 42 inches wide

- Speed of conveyor – 400 feet/minute

COOLING TOWERS

Six Bradford-type by LG Mouchel & Partners, Ltd. Dimensions:

Height of water inlet 31 feet

Internal dimensions

Top 136 feet

Throat 105 feet

Cill 204 feet

Capacity 3 000 000 gallons/hour

Approximate temperature drop 7.5°C

WATER

Water was obtained from the Vaal river where a pump station is installed, and brought to the station by a 0.60m pipeline, 22.5km long. Storage reservoirs at the station had a capacity of 6 000 000 gallons. The capacity of pumps and pipelines were approximately 6 600 gallons per minute. The pumps were remotely controlled from the power station switch operating room.

SWITCHGEAR

The main station busbars were outdoor strung-type, energized at 132kV. 132kV switchgear connected to the duplicate busbars comprised BTH bulk-oil type with a rupturing capacity of 3 500MVA. The oil capacity of each breaker was 2 300 gallons.

Each generator was connected to the 132kV busbars through a generator transformer with a step-up ratio of 11/132kV and a generator circuit breaker.

Outgoing from the 132kV busbars were nine feeders:

- Scafell (6 feeder)

- Vierfontein

- Virginia

- Highveld

Interconnection with Vaal power station was at 88kV, from the 132kV busbars though two 132/88kV coupling transformer banks.

Supply to the station auxiliaries was at 3.3kV for motors of 200hp and over, and at 380 volts for motors under 200hp.

The 3.3kV switchgear was manufactured by South Wales Switchgear, and was indoor-type oil-break with rupturing capacity of 150MVA.

The 380 volt switchgear was manufactured in South Africa and comprised mainly of contractors for motor control, with high rupturing-capacity fuses for fault protection.

SWITCH OPERATING ROOM (CONTROL ROOM)

The switch operating room contained panels for the remote control of all 132kV and 88kV circuit breakers, and for main 3.3kV circuit breakers, as well as all relays for protection of generator and feeder circuits.

Communications services were also centred on the switch operating room.

The control panel suite in the switch operating room was also manufactured in South Africa.

TRANSFORMERS

Generator transformers were rated at 70MVA with forced air-cooling. The rating was reduced to 53MVA with natural draught cooling.

The unit transformers for the turbine and boiler auxiliaries were connected directly to the generator terminals. These were natural cooled units rated at 6.6MVA with a voltage ratio of 11/3.3kV.

The 132/88kV coupling transformers were in two groups each with an aggregated rating of 60MVA. Each group comprised three single-phase units. These transformers were equipped with delta-connected tertiary windings, delivering 3.3kV, which were used to supply general station services, including the residential properties.

WORKSHOPS

Mechanical and electrical workshops were equipped with machine tools and facilities for effecting normal maintenance and all but the heaviest repairs to the power station plant.

MOTHBALLING

The process of closing down Taaibos and Highveld power stations began in 1986. Both power stations were to be placed in reserve storage (“mothballed”) over a period of two years. A “mothballed” power station was one that could be brought back into service if necessary.

DECOMMISSIONING

A decline in mining and industrial activity resulted in decreased demand for electricity. Consequently, a decision was made in 1994 to decommission and dispose of Highveld and Taaibos power stations. Attempts to sell the power stations were unsuccessful. Both stations were no longer viable as operating power stations. Spare parts and the cost of operating staff would be too costly. Also, ESCOM could not guarantee the demand for any electricity generated.

Staff who were employed at Kragbron either transferred to other power stations, or chose early retirement packages. As the closing down of the power station was phased over a number of years, and done in a controlled manner, the final shut-down had little affect on the surrounding community.

In 1999, five people were still working full time at Kragbron. They were to remain until the final disposal of the power stations. All storage facilities were rented to outside users to generate income.

Within the next couple of years all of the buildings will be demolished except for the offices of Taaibos.

The cooling towers will be imploded and coal staiths demolished. All equipment will be sold as parts or scrap.

The residential accommodation has been rented out by Esprop (Eskom Properties department) to non-Eskom families within the surrounding areas, and is currently running at approximately 95%