Vierfontein Power Station

OVERVIEW

Vierfontein Power Station was the first power station to be designed and built by ESCOM in the Rand and Orange Free State Undertaking. This undertaking was established after the Victoria Falls and Transvaal Power Company (the VFP) had been taken over by ESCOM as from 1 July 1948 (the name ESCOM was changed to Eskom in 1987).

Vaal Power Station first produced power in the Free State over 8 years before Vierfontein was commissioned, but although it was financed and owned by ESCOM, it had been built by the VFP. The main purpose of Vierfontein was to assist, as quickly as possible, in meeting the heavy demand for power that was developing on the goldfields of the Free State and in the Klerksdorp area. Initial orders were placed in 1950 for seven 30 MW generators and twelve boilers. The first generator was brought into commercial operation on 4 May 1953. The station was extended to its final installed plant capacity of 360 MW in 1958, which was the full capacity permitted by the resources available at the site. (ESCOM Annual Reports 1950:10, 1952:11, 1958:12; ESCOM Golden Jubilee 1923-1973:21-26; de Villiers 1957:19)

Vierfontein Power Station was in operation for 37½ years, being decommissioned in November 1990. Total net electricity production amounted to nearly 54 thousand GWh (gigawatt-hours), or fifty-four thousand million units. The total coal consumption was 44 million metric tons. (ESCOM Annual Report 1990:17 & Tables of Power Station Operating Statistics; ESCOM News No.158/7 Dec 1990)

BACKGROUND

CONSTRUCTION AND PLANT DETAILS

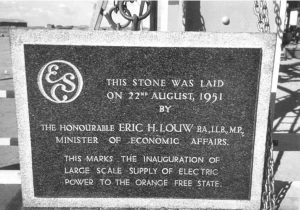

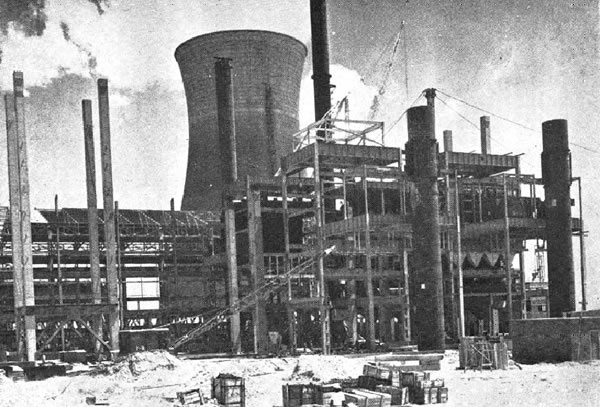

The site was at an altitude of approximately 1290 metres above sea level and was originally open veld. Work on clearing and levelling the ground began in 1949. Construction work commenced in March 1950. Mr EH Louw, Minister of Economic Affairs, laid the power station “foundation stone” at a ceremony on 22 August 1951. Mr AM Jacobs introduced the various speakers, which included Mr Louw, Mr JH Viljoen (Minister of Mines), Mr JJ Fouché (Administrator of the Orange Free State), Mr SR Fleischer (President of the Transvaal Chamber of Mines) and Mr RB Waterston (Escom Commissioner). Several other Government and Escom officials were present, as well as representatives of the mining and engineering industries and of agriculture. Dr JT Hattingh, who the following year became ESCOM’s third Chairman, was also present. (ESCOM Annual Report 1949:8; South African Electrical Review, March 1950:23, Sept. 1951:20-24)

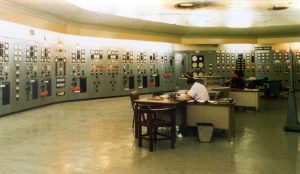

By the end of 1951, the turbine house steelwork for the first three sets had been erected and the first cooling tower was nearing completion. The main station buildings were of steel-framed construction clad with brick filling. Dorman Long (SA) Ltd erected about 9000 tons of structural steel, and approximately 3,6 million bricks were used. The administrative offices were in a separate building at the northern end of the turbine house and connected to it by a short overhead bridge at operating floor level. The control room was in a separate block halfway along the turbine house and also linked to it by a short overhead bridge. By the end of 1952, the turbine house steelwork for the first five sets had been erected, and good progress had been made with the first six boilers and two cooling towers. (Escom Annual Report 1951:10; 1952:11; South African Electrical Review, March 1950:23-27, Sept. 1951:26-31)

The first set was brought into commercial operation on 4 May 1953. By the end of the year three 30 MW sets and four boilers were in service and by the end of 1954 there were seven sets and nine boilers in service. The first units at Wilge and Taaibos had also been commissioned in 1954. Boiler 10 was commissioned on 11 February 1955 and it was decided to extend the station to 360 MW of installed plant. Altogether four boilers were commissioned in 1955, and Generator 8 was commissioned in November. With all these units being commissioned, it was possible to partially relax the control on the maximum demands of consumers on the Rand & Orange Free State Undertaking after the winter of 1955. The control was lifted entirely in the early months of 1956. During 1956 two generators and three boilers were taken into service, and another boiler in 1957. The final two generators and two boilers were installed in 1958, bringing the total installed capacity up to 360 MW by July 1958. (ESCOM Annual Reports 1953:88, 1954:14, 1955:5&13; 1956:97; 1957:97; 1958:12&56; de Villiers 1957: 31; ESCOM-Vierfontein Power Station 1959)

| Year | Generators | Boilers |

| 1953 | 3 | 4 |

| 1954 | 4 | 5 |

| 1955 | 1 | 4 |

| 1956 | 2 | 3 |

| 1957 | 1 | |

| 1958 | 2 | 2 |

| Total | 12 | 19 |

The boiler plant consisted of 19 International Combustion tri-drum boiler units, all fitted with chain grate stokers. These were the largest travelling grate “L”-type louvre mechanical stokers in the world and were manufactured in South Africa from South African materials. (The largest link-type stokers in the world, at that time, were installed at Vaal Power Station). The boiler drums were imported and were solid forged from a single billet of steel. There were no rivets or welds in the shell. Each boiler unit was rated at 210 000 lb/h [26,5 kg/s] normal continuous rating. The steam pressure at the superheater outlet was 635 lb/sq.in. [4,4 MPa (abs)] at a temperature of at 850 °F [454 °C].

Multi-cellular cyclone grit arrestors were fitted and each boiler was provided with a separate steel chimney 200 feet [61 m] high and 9 feet [2,7 m] in diameter. The chimneys were lined with cement to prevent corrosion and were anchored to each other and to the building structure by steel wire stays. The length of the boiler house was 682 feet [208 m] and the height 129 feet [39 m]. Steam was brought from each pair of boilers to a steam receiver manufactured from a solid forging and weighing about 8 tons. The steam receivers were interconnected so that any combination of turbines could be supplied from any combination of boilers. (ESCOM Annual Report 1949:8; South African Electrical Review, March 1950:23; Sept. 1951:26-31; ESCOM-Vierfontein Power Station 1959; ESCOM Golden Jubilee 1923-1973:53)

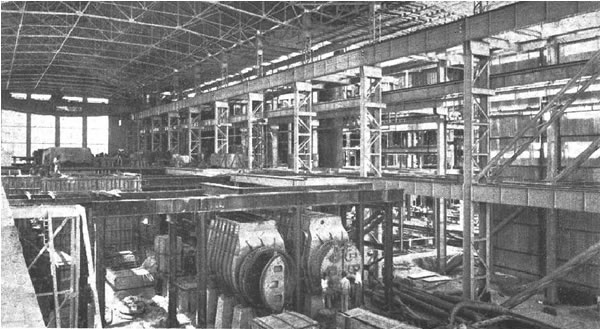

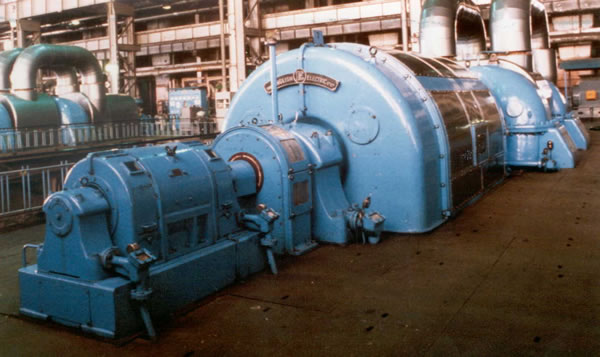

There were twelve 2-cylinder impulse reaction type turbines with 30 MW generators manufactured by English Electric. The length of the turbine house was 809 feet [247 m]. The steam conditions at the turbine stop valves were 600 lb/sq.in. [4,24 MPa (abs)] and 825 °F [441 °C]. The stators were air cooled and the generation voltage was 11 kV. A departure from the design in previous power stations was the use of the unit principle at Vierfontein. With this system, each generator supplies its own auxiliaries and those of its associated boilers, doing away with the need for house sets. (de Villiers 1957:19; ESCOM-Vierfontein Power Station 1959)

Four generators were connected to the outdoor strung-type 88 kV busbars via Metro-Vickers bulk oil circuit breakers with a rupturing capacity of 1 500 MVA. These were designed to be linked to the Klerksdorp and Kimberley area. Eight generators were connected to the 132 kV busbars via Reyrolle small oil volume circuit breakers with a rupturing capacity of 2 500 MVA. These circuit breakers were of the highest rating that had been developed and were first used in South Africa at this station. The 132 kV system fed the Free State goldfields. The busbars were interconnected by two groups of 20 MVA single phase coupling transformers having 8 MVA tertiary windings from which the 3,3 kV station boards were supplied. The generator transformers were rated at 36 MVA and were natural draught cooled. Also connected to each generator was a 2,8 MVA unit transformer from which the auxiliaries and boilers usually associated with that generator could be supplied. The large motors were supplied at 3,3 kV and the smaller motors at 380 V. (South African Electrical Review, March 1950:26-27; de Villiers 1957:19; ESCOM-Vierfontein Power Station 1959)

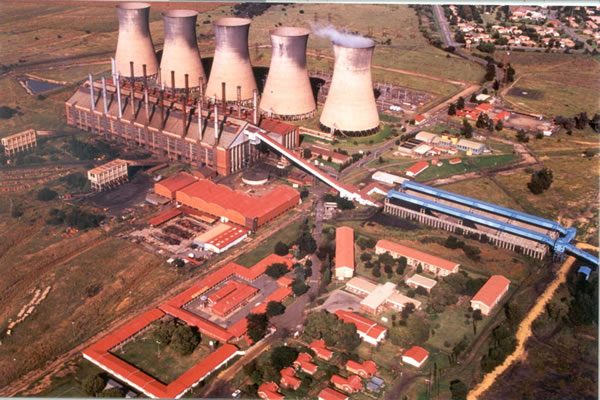

The five Bradford-type cooling towers were designed by Davenport Engineering and built by African Batignolles Constructions (Pty) Ltd. Each had a capacity of 3 million gallons per hour [3,8 kl/s] with an approximate temperature drop of 7,5 °C. The height at the water inlet was 33 feet [10 m] and the height above the sill 285 feet [87 m]. The diameter at the sill was 204 feet [62 m], at the throat 105 feet [32 m] and at the top 136 feet [41,5 m]. The towers were of the divided type to permit cleaning of one half while the other half was in service. The towers were constructed by means of a new procedure first used on two towers at Pretoria. The old method required large quantities of first grade imported timber for support and rigidity and to provide access to the temporary framework of the concrete shell. The new method involved very little use of timber, a continuous ring scaffolding and adjustable steel-lined timber panels for the shuttering being used. These were raised after each lift had been cast. The pump house on the Vaal River, with 14 km of 18 inch [450 mm] pipeline to the power station, came into operation early in 1952 with a temporary pump. The capacity of the permanent pumps and two pipelines was approximately 6 300 gal/min [477 l/s] against a total head of 500 feet [150 m]. The pipelines were of steel lined with concrete. The pumps were remotely controlled from the power station. Water could be discharged into the cooling tower ponds or into storage reservoirs at the station with a capacity of about 6,9 million gallons [31 Ml]. (ESCOM Annual Report 1951:10; South African Electrical Review, March 1950:23-27, Sept.1951:26-31; ESCOM-Vierfontein Power Station 1959)

Capital expenditure during construction amounted to £21,3 million (as at 31 December 1958). This equates to approximately R120 per kilowatt installed. A breakdown of these costs is given below. (ESCOM Annual Report 1959:58; Troost and Norman 1969:180)

| Land and rights | £ 31 004 |

| Buildings and civil works | £ 4 868 175 |

| Machinery and plant | £ 16 446 427 |

| Total | £ 21 345 606 |

OPERATION AND PRODUCTION

During the first four years of its operating life, net annual electricity production at Vierfontein increased steadily to over 1 700 GWh. For the 26 years from 1956 to 1981, net production averaged approximately 1 750 GWh per year. During the closing 7 years, 1984 to 1990, production dropped steadily to almost nil in the last year. Auxiliary consumption in the station averaged approximately 7% of generation, varying from about 6,5% to 8% depending on load factor. Maximum net power remained consistently close to the sent out rating of 336 MW for the years 1958 to 1985, reducing during the closing years (See production chart).

Maximum net annual production was 1 908 GWh, sent out in the year 1975. Maximum thermal efficiency was 23,5% and was achieved in the year 1958. Maximum net power was 354 MW, produced in the year 1980. Statistics for these years, as well as the first and last full years of production, are given in the table below.

| Year | Net Generation GWh | Net Max Power MW | Load Factor (net basis) % | Thermal Efficiency net basis % | Coal Consumed metric ton | Calorific Value of Coal MJ/kg | Cost of Coal R/metric ton |

| 1954 | 959 | 148 | 74,2 | 22,6 | 862 513 | 21,70 | 0,90 |

| 1958 | 1 771 | 304 | 66,5 | 23,5 | 1 279 089 | 21,26 | 1,35 |

| 1965 | 1 722 | 342 | 57,5 | 22,4 | 1 339 485 | 20,68 | 1,71 |

| 1975 | 1 908 | 343 | 63,5 | 22,1 | 1 555 422 | 19,95 | 3,61 |

| 1980 | 1 621 | 354 | 55,0 | 21,1 | 1 485 442 | 18,66 | Not available |

| 1985 | 801 | 335 | 27,2 | 19,6 | 755 010 | 19,45 | Not available |

| 1989 | 62 | 179 | 10,1 | 12,1 | 87 595 | 21,00 | Not available |

Water consumption at the station was 4,34 l/kWh (net) in 1975 and 6,35 l/kWh (net) in 1985. The average during the productive years was about 4,5 to 5 l/kWh (net).

(Data from ESCOM Annual Reports-Tables of Power Station Operating Statistics)

COAL SUPPLIES

The Vierfontein Colliery was part of the Anglo American Corporation and the colliery was planned to produce 155 000 tons/month. The coal was found at varying depths from 30 to 300 feet [9 to 90 m] in a single seam 4 to 7,5 feet [1,2 to 2,3 m] thick. It was brought to the surface by endless rope haulage in incline shafts. The ash content was about 22% and the volatile content about 20%. The calorific value of the coal received averaged over 21 MJ/kg up to 1968. From 1969 until closure of the station the average value was slightly below 20 MJ/kg. (South African Electrical Review, March 1950:23; Sept.1951:26-31; ESCOM Annual Reports-Tables of Power Station Operating Statistics) A slight restriction in output at the station was necessary in 1957, and for the first few months of 1958, due to a shortage of unskilled labour at the colliery. By the end of 1958 the position had returned to normal. (ESCOM Annual Reports 1957:54, 1958:46-47)

Vierfontein Power Station was adversely affected by the Coalbrook mining disaster in the Northern Free State that entombed 437 miners and dozens of ponies. This disaster occurred on 21 January 1960. On 4 March 1960 ESCOM was advised that the East shaft of the Vierfontein Colliery had been closed in the interests of safety. Output at the West shaft was stepped up, but supplies to the power station would be reduced in the ensuing two weeks to 23 000 tons and 25 000 tons respectively, and thereafter to about 27 000 tons per week. The average burning rate at Vierfontein the previous year was over 29 000 tons per week [2000 lb]. An intermediate change of loading at the power station was made.

On the morning of 7 March 1960 the haulage at the Vierfontein West shaft broke down and caused a complete stoppage of coal for 32 hours. On the same evening ESCOM was advised that the ad hoc Committee on safety had ordered the closing of the Coalbrook North Colliery. The closing of the Coalbrook South Colliery followed on 12 March 1960. As a result, a reduction in electricity supply to consumers could not be avoided. Supplies had to be reduced from 13 March 1960. Emergency arrangements had already been made to bring coal to Taaibos and to Highveld from wherever available. Coal from Cornelia colliery near Vereeniging was railed to Taaibos, as Witbank coal proved unsuitable in the pulverised fuel boilers. Klip and Vereeniging had stoker-fired boilers, and Witbank coal was taken there. Coal now also had to be brought to Vierfontein – by rail and by road. The heavy trucks bringing the coal by day and night, had to use the road from the property entrance to the coal off-loading facilities. They went right past the houses of the senior staff, who were unable to sleep a wink for days on end. The beautiful driveway became completely wrecked.

Coalbrook collieries restarted limited production on 18 March 1960 and by the next day power station production was almost back to normal. Full supplies of electricity were restored by the beginning of April 1960. However, a further movement of strata in the North Colliery occurred on 30 March 1961 and as a result of this the Colliery Company decided to abandon the North Colliery. Plans for development of the Eastern shafts were then made. (ESCOM Annual Report 1959:9; Conradie & Messerschmidt 2000:121-123)

ASH DISPOSAL

Each boiler could produce about 4 tons of ash per hour. The ash was removed via paddle tanks and conveyed to three ash bins by conveyor belts and thence to ash dumps by aerial mono-cable ropeway. The ash dumps were located about 1000 feet [300 m] from the station and the estimated capacity of each ash dump was about 13 million cubic yards [10 million cubic metres] at a height of 300 feet [91 m]. At closure of the station the ash dumps were taken over by Roshcon, a Division of Eskom Enterprises, for the making of building bricks. (South African Electrical Review, March 1950:23; ESCOM-Vierfontein Power Station 1959)

STAFF

Vierfontein Power Station was the first accident prevention unit in ESCOM to achieve 3 million man-hours worked without a disabling injury. In recognition of this the station was awarded the RL Straszacker Trophy. On Friday 28 July 1972 the station had the honour of being host to Dr Straszacker, ESCOM’s Chairman, Mr Jan H Smith, who became Chairman in 1980, their ladies and a number of other VIP’s, to celebrate the breaking of this all-ESCOM record. The previous Power Station Manager, Mr Alan Harley, under whose leadership so much had been done, was also present. The trophy was handed to Mr TCA van der Walt, the Power Station Manager at the time. The next day a display of tribal dancing was held and also a soccer match between Vierfontein and Wilge, narrowly won by Vierfontein. (ESCOM Megawatt No.25/1972:22).

During the early 1980’s the staff complement consisted of 774 employees. At closure of the power station the staff members were transferred to other sites or took retirement. (ESCOM Brochure – Klip, Vaal & Vierfontein Power Stations)

COMMUNITY, SPORTS AND RECREATION

A well-built township, laid out on modern lines with parks and tree-lined avenues, was established for the staff about a kilometre from the power station. By 1951 ninety-three dwelling houses, a block of single quarters, a guest house and a boarding house with caretakers’ quarters had been built. The guest house was intended for visiting officials. Additional houses were also under construction. The dwelling houses averaged about 1200 square feet [110 square metres] in area. Amenities such as tennis courts, bowling greens, football fields, swimming bath and a recreation hall for cinema shows and dances were provided. A modern compound was built for the Black employees with kitchen, mess room, recreation hall, washrooms, a hospital and church. Facilities for football and cinema shows were also available. Married Black employees were provided with houses complete with bedrooms, a living room and kitchen. (ESCOM Annual Report 1951:10; South African Electrical Review, March 1951:23; ESCOM-Vierfontein Power Station 1959)

A fine church was built in 1956 by the power station and colliery flock. Harold Williams and Peter Wilson were at that time respectively managers at the power station and at the colliery. Money-raising functions were organised to buy materials and equipment. Various contractors building the power station at that time also donated materials. Men and women worked during weekends and their leisure hours in laying the bricks, sewing linen and making fittings. Although it was an Anglican church, it was also used by other denominations. This church stood on the grounds of the Vierfontein Colliery. (ESCOM News No.188/9 Dec 1992:15)

By 1957 the number of houses in the village had grown to 161 and there were 98 single rooms. There were 415 persons living in the village of whom 116 were employed on the station, 130 were wives and 216 were children. The compound provided for 354 persons. (de Villiers 1957:19)

TRAINING STATION

During 1989 it was decided to use Vierfontein as a training station for young engineers and non-technical management personnel. An intensive eight-week training course was developed, after which students would be able to take the plant from cold reserve to full load and then back to cold reserve again. The advantage of Vierfontein as a training station was that the station had been designed largely for manual control. Electronic systems played a less important role and computer control was not employed as in modern stations. This meant that the various processes involved were more easily visible and could be more readily followed. Problems had to be identified and solutions found by the operator himself, which gave him valuable experience. Specialists were called in at various stages to explain new developments and systems. Later, the training programme was moved to Wilge Power Station in the Eastern Transvaaal, now Mpumalanga. ESCOM News No.124/30 May 1989:3&6, No.127/14 July 1989:7, No.158/7 Dec 1990:1)

CLOSURE AND DEMOLITION

During the 1980’s Eskom had been commissioning its new giant six-pack power stations. But due to a decrease in the rate of growth for the demand of electricity, Eskom began to experience a surplus of generation capacity. The older and less efficient stations were thus no longer required. Some stations were mothballed (stored under special conditions that would mean perhaps months before they could be returned to service) and other stations were totally decommissioned. Vierfontein was one of the stations to be decommissioned. (Conradie and Messerschmidt 2000:259-260)

FAREWELL TO VIERFONTEIN

‘AS WE GATHER HERE TDAY TO SAY AU REVIR TO THIS GRAND OLD THERMAL LADY, WE NEED TO RECALL WHERE OUR ROOTS LIE, AS THEY HAVE GIVEN US DIRECTION AND STRENGTH FOR THE FUTURE.”

With these words Dr Ian McRae, Chief Executive of Eskom, officially closed down the Vierfontein power station on 23 November, after nearly 40 years of operation. Work began on the site in March 1950, and the first set came into commercial operation in May 1953. For the first time in South Africa, 132kV low-oil volume circuit breakers of 2 500 rupturing capacity were employed – at that time the largest to be developed. Vierfontein was built on what was then a newly discovered coalfield, which became known later as Vierfontein collieries. Consequently, transportation of coal was virtually eliminated, and the boiler machinery was adapted especially to burn the low-grade – and therefore cheap coal. Water for cooling purposes was pumped from the nearby Vaal River into five 10 000 litre cooling towers measuring 86.4 m in height, among the highest at that time.

Vierfontein goes down in history.

Vierfontein figured in Eskom history again in 1972 when it achieved a 3 000 000 hour injury free record.

In 1989, despite its reduced output, it was used by Eskom as a training ground for students in power station management.

Vierfontein was selected for this project because electronic processes played a less important role here. Later the programme was moved to Wilge power station.

But as Dr McRae pointed out. Vierfontein power station was more than just towers, turbines and generators. It was also people, and very special people at that. “Without Vierfontein he said “Eskom’s past history would not have been so colorful nor our future as focused and strong. We salute you and your veteran comrades, on whom the strength and reputation was built, for you contribution to our heritage.”

The power station plant was sold as scrap to Ruco Projects and the buildings and cooling towers demolished. Only the office block and workshops have been retained. The township and the water pumping station on the Vaal River have been taken over by a private enterprise, Royal Texas Beef. (Simunye Decommissioning 2004)

BIBLIOGRAPHY

- Conradie SR and Messerschmidt LJM: A Symphony of Power – The Eskom Story – Chris van Rensburg Publications (Pty) Ltd, Johannesburg, 2000

- de Villiers I: The development of the Electricity Supply Commission in the post-war years. In: The Transactions of the South African Institute of Electrical Engineers, February 1957 (Presidential Address)

- Electricity Supply Commission: Annual Reports,1948-1984

- ESCOM Brochure – Vierfontein Power Station – Rand & Orange Free State Undertaking, 1959

- ESCOM Brochure – Klip, Vaal & Vierfontein Power Stations

- ESCOM: Golden Jubilee 1923-1973

- ESCOM Megawatt 1966-1981

- ESCOM News /Eskom News

- ESCOM: Statistical Yearbooks, 1985-1990

- Palser D: Lighting up the Fairest Cape, 1895-1995, A historical record commemorating the centenary of the City of Cape Town Electricity Department

- Reay Dr DB: Some mechanical advances in the power station practice of the Electricity Supply Commission. In: The Certificated Engineer, June 1961

- The Electricity Council (London SW1): A review of ten years of electricity supply in England and Wales 1955-1965

- The South African Engineering Review: Mar, July 1950; Jul, Aug, Sep 1951

- Troost Dr N and Norman HB: Electricity Supply in South Africa. In: The Transactions of the South African Institute of Electrical Engineers, September 1969