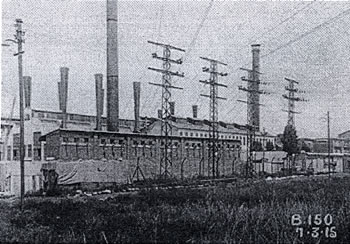

Brakpan Power Station

INTRODUCTION

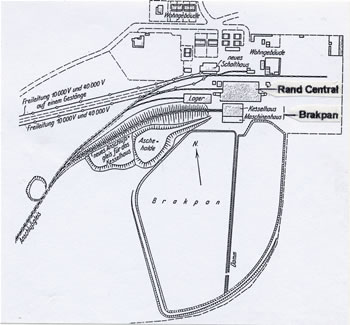

Brakpan Power Station was the first power station to be built by the Victoria Falls Power Company (the VFP) and was brought into operation in September 1908. It was built alongside an earlier station, the Rand Central Electric Works (RCEW), which had been taken over by the VFP in 1907. Brakpan Power Station was sometimes referred to as the “new” Brakpan Station. In more recent literature, the RCEW is often incorrectly referred to as the “old” Brakpan Power Station, but it was not known as such in earlier literature. (South African Mining Journal 1897-1908; Report of the Power Companies Commission 1909:10; Klingenberg 1913)

Brakpan Power Station, as well as Simmerpan, which was commissioned in 1909, was originally planned as an interim measure pending power being brought from the Victoria Falls. It was realised that this scheme would be uneconomic and the Victoria Falls Power Company was changed to the Victoria Falls and Transvaal Power Company in 1909, but still known as the VFP. The design and layout of the first power stations of the VFP were largely due to Professor Dr Klingenberg of Berlin, who was a director and Engineer-in-Chief of the Allgemeine Elektrizitaets Gesellschaft (the AEG). The operating and maintenance staff was drawn mainly from Britain and was under the direction of Dr Bernard Price. Dr Price was a member of the British firm Merz and McLellan from 1901 until he came to South Africa in 1909, where he became Chief Engineer and later General Manager, of the VFP. Two major technical problems were the burning of low-grade coal and the operation of a power system in an area of severe and frequent lightning storms. The VFP was at one time the largest Undertaking of its kind in the British Empire and it provided the basic system from which the present ESCOM system was developed. (South African Mining Journal Feb 1909:1423; Klingenberg 1913; Jacobs 1941:270; Fenwick and Torr 1961:1-2; Troost and Norman 1969:177)

STEAM TURBINES INSTALLED

Up to the end of the nineteenth century, the generators of all steam stations in South Africa were driven by reciprocating piston engines. In overseas installations at that time, the steam turbine was proving itself far more suitable for electrical power generation. It was much more compact, which reduced building costs, the steam consumption was less, it required less attention from the operators and made large savings on lubricants. The higher speed was another big advantage.

The first steam turbo-generator in South Africa was a 50 kW Parsons set installed at the Wynberg Central Station at Cape Town in 1901. The De Beers Consolidated Mines commissioned two large turbo-generators of 1 MW capacity each at their Kimberley Central Power Station in August 1903. A 200 kW turbine was installed at the Porges Randfontein Gold Mine in 1904. At the Driehoek Power Station near Germiston, a 500 kW Curtis turbine was commissioned in August 1904 and a 400 kW turbo-generator was installed at the RCEW in June 1905. Two 1 MW Parsons turbo-generators were installed at the Randfontein Estates Mine in 1907. These were looked upon as an experiment, and gave excellent performance. Larger sets followed, and other mines also installed turbo-generators. (South African Mining Journal, Mar 1905:72; Report of the Power Companies Commission [T.G.13-’10] 1909:10; The Journal of the South African Institute of Engineers Vol IX No 11 June 1911:274; The Journal of the South African Institution of Engineers Vol X No 6 Jan 1912:130 and Vol XII No 1 Aug 1913:1-25; RH Parsons, Development of the Parsons Steam Turbine, 1936:278; Fenwick and Torr 1961:23; Troost and Norman, In: Transactions of the SA Institute of Electrical Engineers, Sep 1969:177)

It was planned to add a 2,5 MW turbo-generator at the RCEW at the end of 1906, but this was not done as the plant was taken over by the VFP. Instead, the Brakpan Power Station was built alongside the RCEW and two 3 MW turbo-generators, supplied by the AEG, were installed. (Machinery, Sep 1896:324; South African Mining Journal, Nov 1906:241, Jun 1907:330; Journal of the Transvaal Institute of Mechanical Engineers, Oct 1908:89-91; Report of the Power Companies Commission 1909:10)

TRANSFORMER AND SWITCH HOUSE

A new transformer and switch house was built on the north side of the RCEW building. It was a three-storey building, measuring 18×30 metres, constructed of steel girders and brick, and was fitted with iron doors. The control room, from where the speed of the turbines was regulated, was situated in this building. Also installed was an accumulator battery of 120 cells, rated at 220 volts and 230-240 amps. The function of the battery was to operate the circuit breakers and to provide emergency lighting. It could also be used as a reserve for one exciter. (South African Mining Journal Jun 1908:399; Klingenberg 1913:2)

POWER TRANSMISSION

The Government consented to an increase in the maximum permitted transmission voltage from 12 kV to 50 kV. A duplicate line of lattice poles was erected extending as far as Simmer Deep, but which would later be extended beyond Johannesburg. The poles were 40 feet in height of which 7 feet were in the ground. The weight of each was one metric ton. Each pole carried one 40 kV circuit and one 10 kV circuit, the former for more distant transmission. Duplicate busbars were provided at the station for each voltage. The lowest point of the line was 26 feet above the ground, or 32 feet at road crossings. The distance between poles averaged about 185 feet in the straight sections. (South African Mining Journal, Nov 1906:241, Aug 1908:719; Journal of the Transvaal Institute of Mechanical Engineers, Oct 1908:89-91)

CONSTRUCTION AND PLANT DESCRIPTION

Invitations to visit the station were extended to members of the South African Association of Engineers, the Institute of Mechanical Engineers and the Mine Managers’ Association. On Saturday afternoon, 22 August 1908, about 160 members availed themselves of the opportunity of going through the first large turbine plant in the Transvaal. The following description of the plant is taken from the Journal of the Transvaal Institute of Mechanical Engineers, Oct 1908:89-90 and the South African Mining Journal, Aug 1908:719. The information was supplied by the management of the VFP at the visit.

The initial installation at Brakpan Power Station consisted of two 3 MW turbine-driven generators and eight boilers. The boilers were in two rows of 4 each and each pair of boilers had one common chimney. The chimney tops were 95 feet above ground level. [This design was adopted for the boiler house because of the limited space between the buildings of the RCEW and the pan of water. – Journal of the SA Institution of Electrical Engineers, Jan 1917:90]

Work on the foundations, which amounted to about 650 cubic yards of concrete, was commenced on 27 January 1908. The steelwork skeleton of the buildings consisted of about 700 tons of steel and erection was completed on 11 April 1908. The turbine house had brick walls and the boiler house walls were of corrugated iron. The length of each was 112 feet. The width of the turbine house was 34 feet and the boiler house 95 feet. The height of the turbine house was 31 feet above ground level and the boiler house roof 72 feet at the highest point.

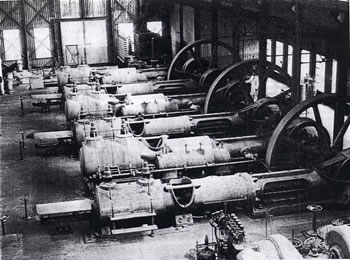

The turbines were built by the Allgemeine Elektrizitaets Gesellschaft of Berlin and the speed was 1500 r/min. They were similar to turbines installed at the Berlin Electricity Works, where results had been very satisfactory. Surface condensers were mounted directly below the turbine and were designed for a vacuum of 93 to 95 per cent. The three-phase generators were direct-coupled to their exciters. Voltage of generation was 10 kV.

The boilers were of the Babcock and Wilcox marine type with superheaters and Green’s economisers. Each boiler had two chain grate stokers and normal evaporation was 20 000 lb/h. The steam pressure was 200 lb/sq.in. with a temperature 670 deg F. [The boilers were designed to burn duff coal (fine waste). Large quantities of this coal were accumulating at the mines as discard. HG Spengel, Chief Engineer of the VFP and previously with the RCEW, was mainly responsible for this pioneering innovation.]

The VFP decided to use the Prat ejector type chimney for their stations. These were found to give the “utmost satisfaction” and great flexibility in boiler house operation. An electrically driven rotary fan propelled cold air through the ejector situated at roof height in the chimney, thereby producing a suction in the flues. A draught of about one inch was usually obtained. A torpedo-shaped damper in the air pipe regulated the pressure of the air jet and the boiler load could be easily regulated to suit changes in the steam requirements. It was claimed to make the plant absolutely smokeless. (Hadley, In: Jour. Institution of Electrical Engineers (London) 1913:14-15)

Coal trucks were shunted from the siding to the top of the boiler house and the coal dumped directly into the bunkers situated above the boilers. The bunkers were of 550 tons total capacity. The railway bridge to the bunker tops weighed nearly 200 tons. [This arrangement was used only at Brakpan Power Station. It was also carried through to the later extensions. Although it reduced the coal handling costs, it was found to be most inconvenient because coal could not be mixed to obtain the best efficiency on the boilers. – Journal of the SA Institution of Engineers, Jan 1917:95]

The pan of water, next to which the station was built, was used for cooling purposes. As it was too small to rely on surface cooling, large spray ponds were built (see photo).

COMPRESSED AIR PLANT

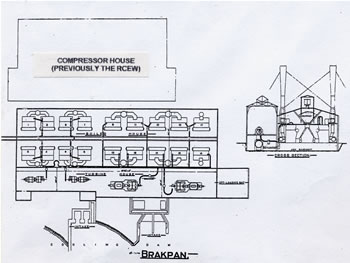

About a quarter of the power demand of a mine was in the form of compressed air, which was used for the operation of jackhammers, pumping and ventilation. Air compressors installed at Brakpan comprised 7600 horsepower [5,7 MW] in 1948. They consisted of:

Three at 800 hp (driven by piston steam engines)

One at 2 550 hp (driven by a steam turbine)

One at 2 650 hp (driven by a steam turbine)

When the Rand Central Electric Works was decommissioned, the building was converted to become the compressor house, and was then considered to be part of the Brakpan Power Station. The compressors at Brakpan were in commercial service until 1962 (see photo). (Otley and Pickles, Journal of the South African Institution of Engineers, Jan 1917:91; Escom Annual Report 1948:6 & 96-97; Draper 1967:124-7; ESCOM Megawatt No 12/1968:39)

1914-15 EXTENSIONS

Two 12,5 MW turbo-generators were added in 1914-15. Ten additional boilers, of a larger capacity, were placed in a double row parallel with the turbine-house. The coal bunkers were divided by bulkheads into nine divisions, four being over the small boilers and five over the larger boilers. The capacity of each of the four small bunkers was 120 tons and of each of the five large bunkers 375 tons. Coal was deposited directly into the bunkers from the coal trucks, as with the first boilers. (Journal of the SA Institution of Electrical Engineers, Jan 1917:90-95)

THE RAND REVOLT 1922

During the 1922 Rand Revolt the Army was mobilised and martial law declared. The VFP power stations were cordoned off by the Army and were kept going by all available staff. At Brakpan Power Station sniping occurred but no damage was done to the plant. The town of Brakpan, however, was a scene of insurrection and terror. The Brakpan rebel commando massacred eight mine officials and special constables at the Brakpan Mine before the revolt was crushed. (Smith 1970:15-17; Symphony of Power 2000:67)

BOILER EXPLOSION 1927

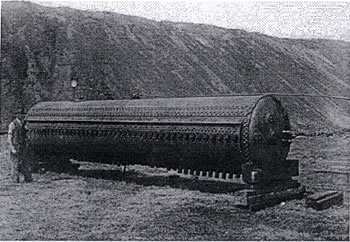

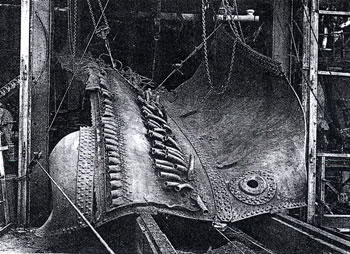

A disastrous boiler explosion occurred in October 1927, wrecking the boiler and extensively damaging the buildings. One of the dished ends of the steam drum was hurled a considerable distance. Four people were killed and others seriously injured. Investigations showed that the failure was due to chemicals in the boiler water causing caustic embrittlement of the steel. (South African Mining and Engineering Journal, Oct 1927:191; Symphony of Power 2000:32 – see photograph)

1935 EXTENSION

A 20 MW set was added in 1935. The station installed capacity was then 51 MW. The 20 MW set was unique in that the turbine was directly coupled to two 20 MW alternators to give greater reactive power. The arrangement made effective use of a spare rotor and stator that had been bought for Vereeniging Power Station. (Fenwick and Torr 1961:3; Troost and Norman 1969:178)

TAKE-OVER BY ESCOM

ESCOM (changed to Eskom in 1987) took over the VFP in July 1948. The VFP staff members were first transferred to the Rand Mines Power Supply Co until the end of the year. As from 1 January 1949 they were formally transferred to Escom. At that time Brakpan Power Station had 48 MW of generating plant in service as one of the original 3 MW generators had been de-commissioned. It also had 7600 horsepower of air compressor plant in service for supplying air to the gold mines. The plant consisted of the following: (ESCOM Annual Report 1948:6 & 96-98)

Generators

Boilers

CompressorsOne at 3 MW, two at 12,5 MW and one at 20 MW

Eight at 28 000 lb/h, ten at 45 000 lb/h and one at 70 000 lb/h

Three at 800 hp (driven by piston steam engines)

One at 2 550 hp (driven by a steam turbine)

One at 2 650 hp (driven by a steam turbine)

Net maximum power produced at Brakpan, after take-over by ESCOM in 1948, was 44,6 MW in the year 1949. Maximum net annual generation was 212,9 GWh, sent out in the year 1952. Thermal efficiency in that year was 13,3% (net basis) with coal of calorific value 21,1 MJ/kg. From 1954 the station was used only for peak loading, due to the commissioning of other new plant. (ESCOM Annual Reports)

CLOSURE

The year 1908, when the Brakpan Power Station was commissioned, proved a tragic year for the Brakpan Colliery. Fire broke out and it had to be sealed off and closed. This was followed by closure of both the Van Dyk and Schapenrust Collieries, and the Rand Colliery became worked out by 1913. However, surveys in 1910 on the farm Modderfontein indicated one of the world’s richest gold finds. Brakpan Mines produced the first gold mined in Brakpan in 1911. The Apex Colliery continued to produce a high-grade coal until it was closed in 1947. By then the VFP, and its subsidiary the Rand Mines Power Supply Co, had commissioned a number of new power stations. Escom also commissioned several large stations in the Eastern Transvaal (now Mpumalanga) and the Free State. Before Brakpan Power Station was taken over by ESCOM in 1948, one of the original 3 MW generators had been de-commissioned. (Smith 1970:11; ESCOM Annual Reports)

After 55 years of service, the power station was finally closed down at the end of August 1963. It was then one of the three longest-serving stations in ESCOM and currently one of the six longest serving to be closed down. Electricity sent out by Brakpan, from take-over by ESCOM in 1948 until closure, amounted to 1 495 GWh (million units). (Eskom Annual Report 1963:55; ESCOM Statistical Yearbook 1995:14-15)

BIBLIOGRAPHY

The South African Mining Journal, 1904-1918

The Journal of the Transvaal Institute of Mechanical Engineers, Oct 1908:89-91. Visit to the Brakpan Station of the VFP

Report of the Power Companies Commission T.G. 13-’10. Government Printer, Pretoria, 1909

The Journal of the South African Institute of Engineers, June 1911. Paper by TPE Butt “Electrification of the Randfontein Estates Mine”

The Journal of the South African Institution of Engineers, Jan 1912. Discussion on Paper by TPE Butt, contributed by HS Van Straubenzee

The Journal of the South African Institution of Engineers Vol XII No 1 Aug 1913. Paper by GM Robertson “Central Power Station Working with special reference to De Beers Central Power Station”

Klingenberg Prof. Dr G “Die Anlagen der Victoria Falls and Transvaal Power Co in Sudafrika” Sonderabdruck aus der Zeitschrift des Vereines deutscher Ingenieure, Jahrgang 1913, Seite 4.

Hadley AE, “Power Supply on the Rand”, In: Journal of the Institution of Electrical Engineers (London), Vol 51, 1913

Price, Bernard, Inaugural Address “Power Supply to the Witwatersrand”, In: Journal of the South African Institution of Engineers, Aug 1916:3-7

Otley TG and Pickles V, Boiler House Operation and Maintenance with Special reference to the Rand Power Companies’ Plant, In: The Journal of the South African Institution of Engineers, Jan 1917:90-99

Parsons RH, “The Development of the Parsons Steam Turbine”, Constable, London 1936

Price, Bernard, “Power Supply on the Rand”, In: South African Engineer and Electrical Review, Oct 1941

Jacobs AM, “The Development of the Electrical Power Supply in the Union of South Africa”, In: The Transactions of the SA Institute of Electrical Engineers, August 1941

ESCOM Annual Reports 1948 to 1963

Fenwick and Torr, “Electric Power Supply to the Mining Industry in the Transvaal and Orange Free State: Its Generation, Transmission and Cost”. Reprinted from The Seventh Commonwealth Mining and Metallurgical Congress, 11 April 1961

Draper J Ralph, “The Engineer’s Contribution – A History of the South African Institution of Mechanical Engineers”, Northern Cape Printers, Kimberley 1967

Escom Megawatt No 12/1968 page 39 (photo of air compressors)

Troost N and Norman HB, “Electricity Supply in South Africa 1909-1969” In: Transactions of the SA Institute of Electrical Engineers, Sept 1969

Smith, Joe X, In: Brakpan, Transvaal, Courier-Gazette Publishers, 1970

ESCOM Statistical Yearbook 1995

Conradie, SR and Messerschmidt, LJM. Symphony of Power, The ESCOM Story, Chris van Rensburg Publications, Johannesburg 2000