Driehoek Power Station

The General Electric Power Company was formed by the Consolidated Gold Fields of South Africa, Limited, to supply electricity at cost to six mines, which were subsidiary companies. These were the Simmer and Jack Proprietary Mines Ltd, Simmer and Jack East Ltd, Simmer and Jack West Ltd, Knights Deep Ltd, Jupiter Gold Mining Co Ltd, and Rand Victoria Mines Ltd. Cecil J Rhodes and Charles D Rudd were Founders and Managing Directors of the Consolidated Gold Fields Company from 1887 to 1895. Rhodes remained a Director until his death in 1902 and Rudd a Director until 1903. The company operated under a concession granted by the Government in July 1897. In early literature (1898-1910) the station is often referred to as the “General Electric Power Company’s Works”. (The Gold Fields 1887-1937; The South African Mining Journal)

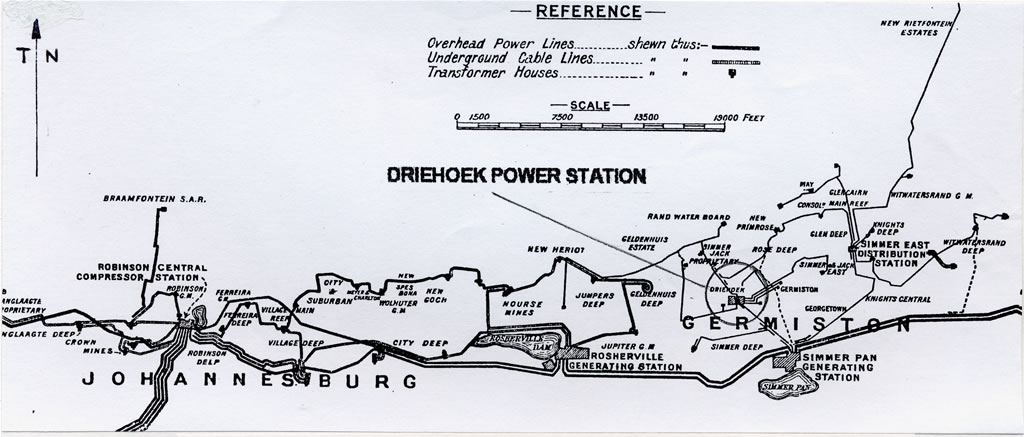

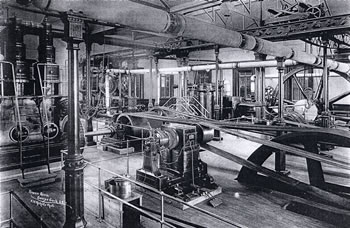

In 1894, the gold mines on the Witwatersrand had about 20 000 horsepower [15 MW] of machinery in use, which was all driven by reciprocating piston steam engines. In June 1902 there were 395 electrical generators installed with a total capacity of over 20 MW and 634 motors with a total of over 16 000 horsepower. By 1906 there was more than 220 000 horsepower [166 MW] of machinery installed. There were about 1300 electric motors in use and approximately 27 MW of electrical generating plant, some of which was by that time steam turbine-driven. However, even then, direct steam-driving still supplied most of the energy from power plants erected at the individual mines for their own requirements. Sometimes the steam engines were directly connected to the plant they were driving, but quite frequently it was through a rope or belt drive (see the photo of a mine power room in 1898). (Annual Reports of the Transvaal Mines Department; Journal of the Transvaal Institute of Mechanical Engineers, Aug 1910:7; Fenwick and Torr 1961:21; JR Draper, The Engineer’s Contribution 1967:122-4)

PLANT DESCRIPTION

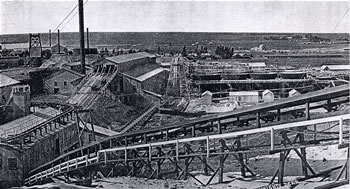

The plant at Driehoek Power Station was at the time among the largest in the world run on a purely private enterprise. AWK Peirce [sometimes spelt “Pierce”] was the General Manager. He was also Vice President of the South African Society of Electrical Engineers. On the invitation of Mr Peirce, members of the Society paid a visit to the works in early 1899. However, no detailed report or plant description appears to have been published by the Society after the visit. (Machinery, April 1899; The Engineer April 1899)

The following plant detail is extracted from The South African Mining Journal, March 1898:524-526 and 546, and March 1899:420)

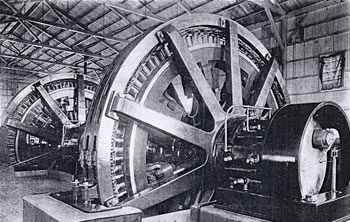

The plans and scheme were prepared by EH Booth of America. J Hubert Davies of Johannesburg signed the contract for supply of the plant. The driving engines for the generators were made by the Allis Co of Milwaukee, USA. The generators were made by Brown Boveri and Co of Baden, Switzerland. The flywheels were supplied by Yates and Thom of Blackburn, England. The exciter engines were made by Bumstead and Chandler of Hednesford, England and the exciter generators by the Electrical Construction Co of Wolverhampton, England. Mr George Mair, electrical engineer to the Consolidated Gold Fields, spent some months overseas at the maker’s works and superintended the erection of the machinery at site.

The boiler house was designed to accommodate 18 Babcock and Wilcox boilers, each of 212 horsepower capacity. The generator house was intended to have four 500 kW generators. By March 1898, two units had been installed and a third was ready for installation. The plant was initially supplied with steam from the surplus boiler capacity of the Rand Victoria Mine. The original contract was for 16 boilers, which were to arrive in time as needed. [However, it would appear that initially only 8 were installed, no doubt due to temporary closure of the mines during the Boer War – Fenwick and Torr 1961:23].

The main engines were of the cross-compound Corliss-valve type. The high pressure cylinders were 24 inches in diameter and the low pressure cylinders 44 inches. The stroke was 48 inches and the speed 75 rev/min. The steam pressure was 130 lb/sq.in. and each engine was capable of developing over 1000 horsepower.

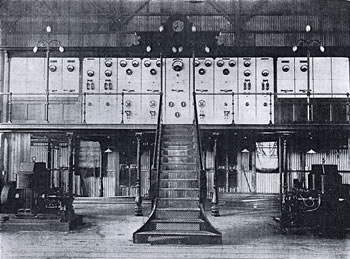

The generators were direct-driven and rated at 500 kW three-phase at 3300 volts and 60 Hz (cycles per second). The rotating portion to which the field magnets were attached also formed part of the flywheel, which weighed about 48 tons and was 20 feet in diameter (see photograph). The exciters were each rated at 24 kW and 75 volts, running at 450 rev/min, direct-coupled to their high speed single-acting compound engines of 44 indicated horsepower. The exciters were installed on either side of the stairway leading up to the switchboard (see photograph).

The main switchboard was designed and built by Brown Boveri of Switzerland. It formed a handsome feature in the generator house, the panels being of polished Italian marble. The front was surrounded by a teak moulding and surmounted by a dial clock. The switchboard was erected on an ornamental iron balcony and was reached by an iron stairway (see photograph). The overhead transmission lines leaving the station were carried on heavy iron poles 36 feet long and buried 6 feet into the ground. The lines were provided with Siemens and Halske lightning arrestors and also Wirt arrestors supplied by the General Electric Co of America.

PLANT EXTENSIONS

The following plant description is taken from “The Engineer”.

The initial plant consisted of three 500 kW Brown Boveri three-phase generators driven by slow speed Allis Corliss engines. The plant was designed for 60 Hz (cycles per second) and the station commenced operation in 1898. As the mines were not far from the station, power could be transmitted at only 3300 volts.

By April 1899 a new 3-phase generator of 500 kW capacity at 3300 volts with a speed of 75 rev/min had been ordered from Brown Boveri of Switzerland. The boilers ordered for this extension were two of 300 horsepower each. However, it would appear that these orders were cancelled, as the fourth set was not installed until 1904, two years after the end of the Boer War (11 October 1899 to 31 May 1902). By July 1899 the mining companies were withholding orders for machinery, as it was not known whether the Boers would destroy the plant in the event of war. Business was at a standstill and many inhabitants of Johannesburg had fled. After the Boer War had broken out, work was temporarily abandoned at the gold mines due to flooding and scarcity of labour. (The Engineer 14 April 1899:376, 28 July 1899:103, 24 November 1899:530, 6 April 1900:369)

In March 1903, while the mines were still recovering from the effects of the Boer War, there was a very small demand for day load. By far the larger portion of the power supply was for lighting, but the use of electricity was again growing daily. At the meeting of the General Electric Power Co held on 27 March 1903, the Chairman said that the “machinery would not be increased until circumstances demand it”. A year later at the fourth annual general meeting held on 25 March 1904, the Chairman said that in order to supply increasing demand, another generator and the necessary boilers had been ordered. (South African Mining Journal, Apr 1903:88-9, Apr 1904:84)

TURBINES INSTALLED

The fourth generator set was driven by a Curtis 500 kW turbine. It was eventually erected in 1904, and was started up in August. Four Stirling boilers were supplied. The set ran very satisfactorily for about six weeks, when an accident occurred on the generator, “though the turbine itself was not injured”. New parts had to be ordered from the makers and these were received just before the year-end. The set was again in service early in 1905. (South African Mining Journal, March 1905:72; E Poole, In: Electrical Review, June 1906:902; Report of the Power Companies Commission 1909:11; Fenwick and Torr, 1961:23)

The first steam turbine installed in the country was a 50 kW Parsons set at Wynberg, Cape Town in 1901, and two 1 MW Parsons-Westinghouse turbines were commissioned at the Kimberley Central Power Station in August 1903. At the Cape Town Industrial Exhibition in 1904, a number of steam turbines were exhibited. These included, among others, a 25 kW Curtis turbine that supplied lights for the exhibition and various other applications of electric motors. A 100 kW AEG turbine was connected to a dynamo and mining locomotive. A Parsons 125 kW single phase turbo-alternator supplied light to Parktown in 1904 and a Parsons 200 kW three phase turbo-alternator was installed at the Porges Gold Mine in 1904. A 400 kW turbine, made by Escher-Wyss of Switzerland, was installed at the RCEW in 1905. The last three, together with the Driekhoek turbine, were among the first turbines to be installed on the gold fields. (South African Mining Journal, Aug 1904:479, Dec 1904:900-950; Journal of the Transvaal Institute of Mechanical Engineers, March 1906:107; Journal of the South African Institution of Engineers, Aug 1913:1-25; Parsons RH, 1936:278)

Early in 1905 AWK Peirce, the General Manager, wrote that water in the Knights Deep shafts had increased considerably, thus creating more demand on the plant. The heaviest load occurred in June [1904] when the average for the month was 1,087 MW. The total output for the year [1904] was 8,657 GWh (million units). This was an increase in load of 30% over the last half of 1903 and an increase of 89% over the whole of 1903. All three generators had been run for the greater part of the year. HH Web, in his report as consulting engineer, stated that in order to meet the demand for power it would be necessary to still further increase the capacity of the plant immediately. (South African Mining Journal March 1905:72)

At the sixth ordinary general meeting of the General Electric Power Co, the Chairman said that some of the new plant [for the fifth set] had come forward and it was expected to be in operation by the close of that year [1906]. (South African Mining Journal, April 1906:99)

According to Fenwick and Torr (1961:23), the set installed in 1906 was driven by a 1 MW Curtis turbine and a 250 kW DC auxiliary set was also installed. The total installed plant was reported as then being 3,25 MW. However, according to the Report of the Power Companies Commission (1909:11), Jacobs (1941:259) and Troost and Norman (1969:177), the plant had a capacity of 2,5 MW. The Government Mining Engineer, in his Annual Report for the year to June 1910, lists the Driehoek plant as having a capacity of 3 MW. Arthur Hadley, Managing Director of the VFP, stated that the plant had a capacity of 2,5 MW in 1906. (Transvaal Mines Dept, Annual Report of the Government Mining Engineer Year Ending June 1910:29; AE Hadley, In: “Power Supply on the Rand”, Journal of the Institution of Electrical Engineers (London), Mar 1913:2; Bernard Price, “Power Supply to the Witwatersrand”, Journal of the South African Institution of Engineers, Aug 1916:6)

Power was also sold from Driehoek to the Germiston Municipality and township of Georgetown. E Poole, in The Electrical Review of June 1906 listed that there were 493 consumers in Germiston, using 13 000 lamps each of 8 candlepower, as well as a motor load of 245 horsepower. Street lighting consisted of 10 arc lamps and 34 incandescent lamps. The Driehoek plant capacity then was 2 MW [evidently after the fourth set had been installed] and consisted of 2 Babcock and Wilcox boilers and 8 Stirling boilers, 3 Allis engines and a Curtis turbine, 3 Brown Boveri generators and one by GEC. A 1750 kW alternator and 6 boilers were to be installed [as stated, but it would appear that a 500 kW set was actually installed]. Units sold [1904] amounted to 8,657 kWh. (E Poole, In: Electrical Review, June 1906:902)

TAKE-OVER BY VFP AND CLOSURE

In February 1907, the General Electric Power Company with its plant and concessions was taken over by the Victoria Falls Power Company (the VFP). [It was later re-named the Victoria Falls and Transvaal Power Company.] The VFP had been registered in October 1906 and planned to build a number of large central stations using steam turbines. The first of these would be the Brakpan and Simmerpan stations. Power would be offered at about 0,5d per unit, representing a saving of 40% to the mines. (South African Mining Journal, Jan 1907:421, June 1907:327; Report of the Power Companies Commission 1909:10 (T.G. 13-’10); Fenwick and Torr 1961:24)

By October 1907, both the RCEW and the Driehoek Power Station were “supplying power to their utmost capacity and it [was] found necessary to enlarge the capacity of the Germiston [Driehoek] station [evidently the fifth set] pending the erection of the new central station [Simmerpan] of 24 000 horse-power capacity [18 MW], the machinery for which [was] in an advanced stage of construction”. (South African Mining Journal, Oct 1907:163)

By October 1908 the old plant [presumably the three reciprocating engines] at Driehoek was being completely dismantled and the new plant of the Simmerpan Power Station was expected to be ready for use in about five months time. The new plant at Brakpan was already running. However, the turbines at Driehoek were run throughout 1908 and were still at full load in July 1909. (South African Mining Journal, Oct 1907:163, Oct 1908:975, Jul 1909:505)

The Rand Central Electric Works and the General Electric Power Company’s Driehoek Power Station both failed to compete with the cost of steam power in the mines. Their prices were about 2d per unit, which was more than twice that of steam power in the mines. (Report of the Power Companies Commission 1909:10 (T.G. 13-’10); Fenwick and Torr 1961:24)

The plant was reported as being most reliable but not designed for economy. The steam consumption of the slow speed piston engines at Driehoek was 31 lb/kWh. That of the turbines was about 22 lb/kWh against only 14 lb/kWh at Simmerpan. [The turbines of a modern Eskom station, for example Tutuka, consume 501 kg/s at 609 MW, giving a steam consumption of 3 kg/kWh or 6,6 lb/kWh, which is only 21% of the consumption of the Driehoek piston engines]. (Fenwick and Torr, 1961:23, quoting AE Hadley, Chairman of the VFP, in 1910)

Driehoek Power Station was finally closed down in 1911, after the VFP had commissioned their new Simmerpan Power Station. (Fenwick and Torr 1961:22-4)

BIBLIOGRAPHY

Machinery (official organ of the South African Society of Electrical Engineers), 1896-Sep 1899

The Electrician, 1896-1907, Journal of Electrical Engineering, Industry and Science

The South African Mining Journal [and Financial News/Commerce and Industries], 1897-1915

The Engineer, 1898-1901

Engineering, 1898-1909

Journal of the Mechanical Engineer’s Association of the Witwatersrand, 1902-1913

Transvaal Mines Department – Annual Reports 1904/05-1909/10

The Electrical Review, June 1906

Journal of the Transvaal Institute of Mechanical Engineers, 1906

Report of the Power Companies Commission 1909 [T.G. 13-’10]

Klingenberg, Prof Dr G, Die Anlagen der Victoria Falls and Transvaal Power Co. in Sudafrika, Sonderabdruck aus der Zeitschrift des Vereines deutscher Ingenieure, Jahrgang 1913, Seite 4

Hadley AE, “Power Supply on the Rand”, In: Journal of the Institution of Electrical Engineers (London), Vol 51, Mar 1913:2-17

Bernard Price, Inaugural address “Power Supply to the Witwatersrand”, In: The Journal of the South African Institution of Engineers, Aug 1916:3-7

“The Gold Fields 1887-1937”, The Consolidated Gold Fields of South Africa Ltd, London, 1937

Parsons RH, The Development of the Parsons Steam Turbine, Constable & Co, London, 1936

Jacobs AM, The Development of Electrical Power Supply in the Union of South Africa, In: The Transactions of the S.A. Institute of Electrical Engineers, Aug 1941

Fenwick W and Torr HM, Electric Power Supply to the Mining Industry in the Transvaal and Orange Free State: Its Generation, Transmission and Cost, In: Reprint from “The Seventh Commonwealth Mining and Metallurgical Congress”, 11 April 1961

Draper J Ralph, The Engineer’s Contribution. A History of the South African Institution of Mechanical Engineers 1892-1967, Northern Printers, Kimberley 1967

Troost Dr N and Norman HB, Electricity Supply in South Africa 1909-1969, In: The Transactions of the S.A. Institute of Electrical Engineers, Sept 1969