Rand Central Electric Works

INTRODUCTION

The Rand Central Electric Works (RCEW) was built by the Rand Central Electric Works, Limited, and commissioned in 1897. It was the first public utility central power station to be constructed in South Africa and the first to transmit power at 10 kV. [The first central power station in the country had been financed by the Cape Colonial Government and built by the Table Bay Harbour Board in 1891]. The RCEW should not be confused with the later Brakpan Power Station built by the Victoria Falls Power Co Ltd, (the VFP), although the stations stood alongside one another. In more recent literature the RCEW is often referred to as the first, or the “old”, Brakpan Power Station. However, in its day it was named the Rand Central Electric Works and sometimes the Rand Central Power Plant or the Rand Central Power Station. (Machinery Sept 1896:325; The Electrician Dec 1897:291; Klingenberg 1913:2)

The Company, “The Rand Central Electric Works, Limited”, was established in 1895. It was financed by British capital and was administered from London. There was also a South African local board. The project was due to the enterprise of Messrs Siemens and Halske of Berlin, who wished to create a market in South Africa. [The first central power station in Germany was erected in 1885, and by 1890 Siemens and Halske were supplying 500 horse-power dynamos to Berlin]. In July 1894, together with John Hubert Davies, an electrical engineer of Johannesburg, a grant from the South African Republic had been obtained “to lay and have electric conductors for the transmission of power to the mines along the Witwatersrand [Ridge of White Waters]”. This grant was made over to the Rand Central Electric Works, Limited. (Elektrotechnische Zeitschrift, vol v, 1890:53, In: Minutes of Proceedings of The Institution of Civil Engineers (London) Vol C, 1889-1890, Pt II; Report of the Power Companies Commission 1909:9; Fenwick and Torr 1961:22)

The Rand Central Electric Works was among the first in the country to generate three-phase alternating current. It was the first company to supply electricity to the gold mines on the Witwatersrand, excluding those mines that had their own plant. It was situated near the shaft of the Brakpan coal mine and a franchise was also obtained for the lighting of Johannesburg. In 1903 Johannesburg City was purchasing about 50% of its power from the RCEW. (Johannesburg Town Council statistics and Minutes of Meeting 12 Jan 1903:1156)

BACKGROUND

Up to the end of the nineteenth century, the generators of all steam stations in South Africa were driven by reciprocating piston engines. In overseas installations at that time, the steam turbine was proving itself far more suitable for electrical power generation. It was much more compact, which reduced building costs, the steam consumption was less, it required less attention from the operators and made large savings on lubricants. The higher speed was another big advantage.

The first steam turbo-generator in South Africa was a 50 kW Parsons set installed at the Wynberg Central Station at Cape Town in 1901. The De Beers Consolidated Mines commissioned two large turbo-generators of 1 MW capacity each at their Kimberley Central Power Station in August 1903. A 200 kW turbine was installed at the Porges Randfontein Gold Mine in 1904. At the Driehoek Power Station near Germiston, a 500 kW Curtis turbine was commissioned in August 1904 and a 400 kW turbo-generator was installed at the RCEW in June 1905. Two 1 MW Parsons turbo-generators were installed at the Randfontein Estates Mine in 1907. These were looked upon as an experiment, and gave excellent performance. Larger sets followed, and other mines also installed turbo-generators. (South African Mining Journal, Mar 1905:72; Report of the Power Companies Commission [T.G.13-’10] 1909:10; The Journal of the South African Institute of Engineers Vol IX No 11 June 1911:274; The Journal of the South African Institution of Engineers Vol X No 6 Jan 1912:130 and Vol XII No 1 Aug 1913:1-25; RH Parsons, Development of the Parsons Steam Turbine, 1936:278; Fenwick and Torr 1961:23; Troost and Norman, In: Transactions of the SA Institute of Electrical Engineers, Sep 1969:177)

It was planned to add a 2,5 MW turbo-generator at the RCEW at the end of 1906, but this was not done as the plant was taken over by the VFP. Instead, the Brakpan Power Station was built alongside the RCEW and two 3 MW turbo-generators, supplied by the AEG, were installed. (Machinery, Sep 1896:324; South African Mining Journal, Nov 1906:241, Jun 1907:330; Journal of the Transvaal Institute of Mechanical Engineers, Oct 1908:89-91; Report of the Power Companies Commission 1909:10)

At the end of the Nineteenth Century coal and gold were being discovered in various parts. Coal discovered on a farm called Weltevreden led to the construction of Brakpan Colliery, and the name “Brakpan” appeared for the first time. Due to the apparent abundance of coal in the area, Apex Colliery opened nearby in 1892, and Schapenrust Colliery opened in 1896. Transporting coal from the collieries to the Witwatersrand gold mines and to the growing needs of Johannesburg by ox-wagon was slow and expensive. To overcome the problem, the Volksraad built a railway line connecting the coal and gold mines. It became known as the Rand Tram. The opening of the mines and the development of infrastructure resulted in an influx of people, and Brakpan was born. (Smith, JX 1970:5)

Coal mining methods at the time produced large quantities of waste coal because steam engines and railway locomotives (the main consumers) could not use coal below a half-inch in size. Sammy Marks, who owned the Vaal Colliery, believed that the waste coal could be used to generate electricity for Johannesburg and the mines. Drilling in mines, at that time, was done by hand. As gold mines became deeper, hand drilling became more impractical. From 1889, a company called Siemens and Halske owned the concession to supply Johannesburg and Pretoria with electricity. In 1894, Siemens and Halske was supplying the Witwatersrand mines as well. The mining industry was expanding and the increasing population of Johannesburg was also demanding more electricity. But electricity was still being supplied by small individual lighting plants, which were not able to cope with the increasing demand. Another method of supplying electricity was becoming necessary using larger central stations.

At this point in time Mr NJ Singels came out from Germany to study the possibilities. The result was that a company, the Rand Central Electric Works, Limited, was founded. This company obtained the concession from Siemens and Halske, and began planning the construction of the first power plant that would supply electricity commercially to the Witwatersrand mines. It was the rapid development of the mining industry that led to the birth of the town of Brakpan, and the construction of a power plant in Brakpan would allow the continued development of the mining industry.

In an interview with the journal “Machinery” in 1896, Mr NJ Singels said he came out from Europe in 1894 to study the possibility of electrical power transmission along the Witwatersrand. [“Machinery” was the official organ of the South African Society of Electrical Engineers]. Mr Singels said he soon abandoned the idea of water power. After trials with coal from different mines, he entered into an agreement with the Transvaal Coal Trust Company and obtained a favourable site for the erection of a central generating works at Brakpan. Water rights for condensing purposes were also secured. A grant was obtained from the Government to pass a transmission line along the Rand. He amalgamated with Hubert Davies who had wide experience in this field.

Mr Singels said he then returned to Europe at the beginning of 1895. The Company, the Rand Central Electric Works, Limited, was registered in London in March 1895. Messrs Siemens and Halske of Berlin were the contractors. Mr Singels returned from Germany and building operations were started by 1 September 1895. Residential buildings, a boarding house and quarters for married and for unmarried men were erected. These were constructed in an approved style in order to attract skilled workmen from Europe and to retain them in service. A coach-house and stable was also built for the Manager. (NJ Singels, In: Machinery, Sept 1896)

According to the contracts, the works should have been completed within 18 months of 3 May 1895. However, the contract date was extended to 1 January 1897. Power was first generated in May 1897. By the end of 1897, all four sets were available but only three were sufficient to supply the power contracted for. The fourth set was kept in reserve. (Annual ordinary general meetings, RCEW Ltd, London, In: SA Mining Journal Jan 1898:368-9, May 1898:700)

While construction of the plant was being planned, gas lamps were being erected in Johannesburg as well as forty-two electric lamps in busy areas. [The first electric streetlights in Johannesburg were supplied from two dynamos driven by small 30 horse-power piston engines using gas produced from coal in June 1892, ten years after Kimberley had electric streetlights and three months after Rondebosch in Cape town.] The Star Newspaper reported the overwhelming number of applications for electricity in the area and monitored the construction of the power plant. The chimneys were to be among the highest in the district and were planned to reach a height of 150 feet. The plant would not meet the number of applications for electric current, but would supply Braamfontein, Hospital Hill, Doornfontein, and Jeppestown.

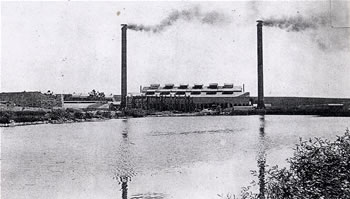

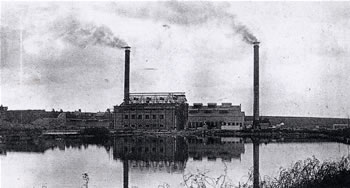

The Rand Central Electric Works, Limited, had chosen a site on the north edge of Brakpan Dam (known in 2001 as Jan Smuts Dam). Water from the dam would be used for cooling, and a railway line was laid from Brakpan Colliery to the power plant to supply coal.

PLANT DESCRIPTION

Messrs Siemens and Halske, of Berlin, were responsible for the construction and erection of the whole of the plant, which was under the superintendence of Mr Singels. He was assisted by Mr Singer, as Messrs Siemens and Halske’s Engineer, and who later became manager of the works. (Machinery, Oct 1897:247)

The engine house was 200 feet long by 50 feet wide and the boiler house 225 feet long. The foundations for the engines were built in concrete in one piece throughout the entire building. They rested on hard rock at a depth of about 14 feet below the surface of the ground. There were eight Kleinmitter water tube boilers, each of 3400 square feet heating surface. The boilers were of the same size and construction as those in the electric light stations of Berlin. The two iron chimneys were 16 feet in diameter at the bottom and 10 feet at the top. They were 150 feet high. The station was situated about two and a-half kilometres from the colliery. A downgrade existed all the way from the colliery to the station, the trucks being returned by the electric company’s own locomotives. (NJ Singels, In: Machinery, Sept 1896; The Electrician, Dec 1897:290; Journal of the Transvaal Institute of Mechanical Engineers, Vol IV, Mar 1906:120)

The initial installation consisted of four triple expansion reciprocating engines of the vertical marine type manufactured by Hartmann (Sachsische Maschinen Fabrik of Chemnitz). The operating steam pressure was 180 lb/sq.in. The high pressure cylinders were 22,5 inches in diameter, the intermediates 36 inches and the low pressure 57 inches. The stroke was 35,5 inches. Each engine had a normal output of 1000 brake horse-power. The surface condensers were also made by Hartmann of Chemnitz. Coupled direct to the engine was a 700 kW three-phase generator. At first three engines were to be in use with the fourth acting as a spare. This would give the station an output of 2,1 MW. Due to the speed being only 100 rev/min the internal diameter of the armatures was 15 feet. Each dynamo weighed 80 tons and for reasons of transport, was constructed in four pieces. Voltage was stepped up from 700 volts to 10 kV for transmission. (Machinery, Sept 1896; The Electrician, Dec 1897:290-1; Proceedings of the South African Association of Engineers and Architects, Vol V, 1899:129-135; Journal of the Transvaal Institute of Mechanical Engineers, Vol IV, Mar 1906:120-121; Fenwick and Torr 1961:2

VISIT BY PRESIDENT PAUL KRUGER AND VOLKSRAAD

Sir Charles Rivers Wilson was Chairman at the annual ordinary general meeting of the Rand Central Electric Works, Ltd, held in London on 14 Dec 1897. He said that on 18 September 1897 the works were honoured with the presence of President Kruger, General Joubert, members of the Executive Council of the Volksraad, and a large party from both Pretoria and Johannesburg. A very good arrangement was made with the President for an extra supply of water. (South African Mining Journal, Jan 1898:368-9)

Also present were Mr Kock, Commandant Cronje, Dr Leyds, the Minister of Mines, the Postmaster General, Mr Middelburg and representatives of the mining industry. The guests were cordially welcomed by Mr A Brakhan, Chairman of the Local Board of the Rand Central Electric Works, Mr Singels, the General Manager and Mr J Singer, previously of Siemens and Halske, the Manager. In the course of his speeches, the President gave the assurance that the Government and the Raad were desirous to assist the industry and would do their best to reduce railway tariffs, the price of dynamite and the cost of imports. Notwithstanding the great amount of work they had to deal with, the Government and Volksraad had left their duties to come out to the works because they knew that works of that description increased the prosperity of the [Transvaal] Republic. He admitted that the mining industry was a staple source of revenue to the State, and whose welfare the Executive and the Volksraad did their best to promote. [Notwithstanding the assurances given, three years and four months later the plant was extensively sabotaged by a Boer commando – see below.]

After the President had watched the working of the machinery and followed the explanations of Mr Singer “with evident interest”, they adjourned to one of the houses where they had a brief rest and some light refreshments. Shortly after noon, about 120 guests and officials sat down to luncheon in a marquee. After further speeches the party finally left on the return journey at 2.30 o’clock. (The Star, 18 Sept 1897 [Sporting Edition 6.30 pm, page 5], 20 Sept 1897 [First Edition page 4]; Machinery, Oct 1897:247)

In June 1899 members of the South African Association of Engineers also paid a visit to the plant. (Proceedings of the South African Association of Engineers and Architects, Vol V, 1899:129-135)

OPERATION AND THE BOER WAR

The Rand Central Electric Works, Limited, was the first company on the Witwatersrand to transmit power at high voltage. The bulk supply to Johannesburg was at 10 kV, transformed down to 2 kV at Berea Street. In the first years there were frequent interruptions of the supply due to the severe lightning conditions on the Witwatersrand. This caused a good deal of misgiving to the mines, some of which considered cancelling their contracts on account of the unreliability of the supply. The cost of electricity from the station also failed to compete with the cost of steam power in the mines. It was not until the Victoria Falls Power Co built their power stations using the far more efficient turbine instead of slow speed reciprocating piston engines, that electric power could take over from steam power in the mines. (South African Mining Journal, Mar 1898:548; Johannesburg Town Council Minutes of Meetings, Jan 1903:1156; Fenwick and Torr 1961:22-24)

In the year the plant was constructed, the Johannesburg Lighting Department was unable to keep up with the growing demand for electricity and made an agreement with the Rand Central Electric Works to buy 500 kW as a daily supply. By 1898, there were an extra 761 electric lights in Johannesburg bringing the total number to 803, while only 477 gas lights lit up the streets. The number of consumers of electricity rose to 520 surpassing the 480 consumers of gas.

Residents in Johannesburg were not the only people to benefit from the expanding supply op electricity. The Rand Central Electric Works erected forty five miles of main transmission lines between the station and the property of the Main Reef Gold Mining Company on the farm Paardekraal, ten miles west of Johannesburg. Most mines were still equipped with steam engines and a handful had their own electric generators, But more and more were making use of the supply from the Rand Central. By 1898, many gold mines along the Reef were drawing electricity from the “main wire” of the Rand Central Electric Works, and the yield of gold from the Witwatersrand mines was increasing dramatically. Brakpan as a town was growing steadily, but the turbulent years of the early Twentieth Century were to bring many troubles.

By the time the South African War broke out in October 1899, the power lines from the Rand Central had already reached and passed through Johannesburg, but the expanding use of electricity would be hampered by the war. Not only did the war damage the mining industry, which the works served, but the station itself suffered extensively. Early on 20 January 1901, Field Cornet Meyer led a Boer commando onto the property of the Rand Central Electric Works. The Resident Engineer was woken up and informed that General Louis Botha had given instructions to destroy the generators. Dynamite charges were attached to all four of the engines and detonated. Only one of the engines escaped severe damage. On leaving, the commando threatened to destroy the entire station if any repairs were made.

The British troops had occupied Johannesburg on 31 May 1900, but with too few troops available to provide protection for the resident workers, the power station was left idle until September 1901. An exchange of confidential letters ensued between Spengel (General Manager) and Lionel Curtis (acting Town Clerk of Johannesburg). Mining was virtually stopped for two years during the Boer War. (Shorten 1966:599; Conradie and Messerschmidt 2000:24)

The Government was requesting that the station repair its generators and supply the electricity that would light up Johannesburg. The insistence of the Government was based on the belief that a city left dark at night provided a morale boost for the Boers and showed weakness on the British side. Even though the Rand Central Electric Works was not contractually obliged to provide electricity under such a threat, Spengel agreed to restart the station if thirty to forty men were sent to provide protection. The troops, however, were not initially available. The Government repeatedly requested the starting up of the power station but Spengel refused to endanger the plant and its workers. Eight months passed until, in September 1901, the generators could be restarted. The following year the Peace of Vereeniging was signed, the two Boer republics became British colonies, and the Rand Central Electric Works was claiming damages from the Government. It was claimed that “the works were raided simply in consequence of the assistance they were able to render the military authorities”. (Sir Rivers Wilson, Chairman, at the annual general meeting held in London on 26 June 1903, In: South African Mines, Commerce and Industries, July 1903:444)

By the end of 1897 about 1200 horse-power [900 kW] was being supplied. Electricity production at the station in the year 1897 was about 4,0 GWh. It increased to 6,2 GWh in 1898 and 7,4 GWh in 1899. Due to the Boer War breaking out in October 1899, production in 1900 was only 3,3 GWh and in 1901 only 0,8 GWh. In 1902 production increased again to 7,1 GWh and in 1903 to 8,2 GWh. (South African Mining Journal, May 1898,700; Fenwick and Torr 1961:22)

In 1902, HC Behr (Consulting Engineer to the Consolidated Gold Fields Group) wrote a revolutionary paper advancing mining techniques. He envisaged far greater use of electricity underground. The war had nearly halved coal output, but the industry was recovering and the Rand Central Electric Works was receiving coal from Apex, Schapenrust, Brakpan, and Rand Collieries. In 1903, Brakpan Mines had been established and gold was to be mined in the area. The Rand Central Electric Works would be available to supply electricity for the new gold mines and the recovering coal mines. Furthermore, the talk of gold in the area brought an influx of people. Brakpan was expanding, its first school was built in 1903, and the growing population was to be serviced by the power station, which would be needed to meet growing industrial and public needs. (Smith, JX, 1970:7, 9, 11; Conradie and Messerschmidt 2000:27)

TURBINE INSTALLED

By June 1903 the plant was working at full capacity. Mr Spengel, the manager, was negotiating a contract in Germany for a fifth Siemens and Halske generator to be driven by a 1000 hp triple expansion engine of the vertical marine type. Re-arrangement of oil filters and steam traps had been made to provide room for the extension of the plant. Two multi-tubular boilers of modern design were also to be provided. It was expected that this machinery would be installed within a year. (South African Mines, Commerce and Industries, July 1903:444)

It would appear that the fifth triple expansion piston engine was not supplied. Instead, a 400 kW turbo-generator was installed in June 1905, operating at 3000 rev/min. The turbine was manufactured by Escher-Wyss of Switzerland and the generator by Siemens-Schuckurt. The condenser was supplied by Balcke. (Journal of the Transvaal Institute of Mechanical Engineers, March 1906:107&121; Report of the Power Companies Commission [T.G.13-’10] 1909:10)

The first turbine-driven generator in the country was a 50 kW Parsons set installed at Wynberg, Cape Town in 1901. Two 1 MW Westinghouse-Parsons turbo-alternators were commissioned at the Kimberley Central Power Station in 1903. A 200 kW set was installed at the Porges Randfontein Gold Mine and a 500 kW turbine at the Driehoek Power Station in 1904. (South African Mines, Commerce and Industries, Mar 1905:72; Journal of the Transvaal Institute of Mechanical Engineers, Jan 1912:130; RH Parsons 1936:278)

On Saturday 27 January 1906, about 150 members of the Institute of Mechanical Engineers made a visit to the RCEW at the invitation of Mr HG Spengel, the Managing Director. They arrived by special train and were received by Mr Spengel and Mr Mauss, Manager at the Works. The turbine generator, recently installed, was a “great centre of attraction”. (Journal of the Transvaal Institute of Mechanical Engineers, March 1906:120-121)

CLOSURE

At the end of 1906, with a total installed plant capacity of 3,2 MW, it was planned to install a 2,5 MW turbo-generator. However, this was not done because events took an important turn. The Victoria Falls Power Co bought out the General Electric Power Co and their Driehoek Power Station in February 1907. They had also raised large funds for the erection of a new central station. In the face of this competition the RCEW Ltd were forced to negotiate with the VFP, whereby the company would also be taken over. The VFP then built a new station, the Brakpan Power Station, alongside the RCEW and installed two 3 MW turbo-generators. The first of these was brought into service in September 1908. Annual production at the RCEW in 1909 was 22,8 GWh. A little later, when the VFP had also commissioned the Simmerpan Power Station, the less efficient Rand Central could be closed down. (South African Mines, Commerce and Industries, Jun 1907:330; Report of the Power Companies Commission [T.G.13-’10] 1909:10; Hadley 1913:2; Fenwick and Torr 1961:22-4)

After the station had been closed down, the building was used to house plant for supplying compressed air to the mines. This plant was then considered to be part of the Brakpan Power Station. (Journal of the South African Institution of Engineers, Jan 1917:91; see also photo Escom Megawatt No 12, 1968:39)

RECREATION

Over the years the recreation hall at the RCEW had built up a respectable reputation. Brakpan was a relatively small town and so Apex Colliery, Brakpan Colliery and the RCEW made their recreation halls available for use by the community. Concerts, dances, church services, political meetings, and all other social events were held in these halls. The RCEW hall was particularly popular on Saturday nights when entertainment began with a concert. At the end of each concert, dancing would continue until midnight when meals were served, after which dancing would resume until six on Sunday morning. Because Brakpan was such a comparatively small community, there was very little crime and the only policeman available in the area was at Schapenrust, three miles southeast of Brakpan. With no local authority in the Benoni-Brakpan-Schapenrust area, the mines and the RCEW did well to supply their own services and amenities. (Smith JX, 1970:9)

BIBLIOGRAPHY

Minutes of Proceedings of The Institution of Civil Engineers (London) Vol C, 1889-1890, Pt II

Machinery (official organ of the South African Society of Electrical Engineers) 1896-1900

The Electrician 1896-1907, Journal of Electrical Engineering, Industry and Science

The Star (Newspaper), 18 and 20 September 1897

The South African Mining Journal/South African Mines, Commerce and Industries, 1897-1908

Proceedings of the South African Association of Engineers and Architects Vol V 1899, Visit of the Association to the Rand Central Electric Works, Brakpan

Journal of the Mechanical Engineer’s Association of the Witwatersrand 1902-1912

Journal of the Transvaal Institute of Mechanical Engineers, 1906-1912

Report of the Power Companies Commission 1909, (T.G. 13-’10)

Klingenberg, Prof Dr G, Die Anlagen der Victoria Falls and Transvaal Power Co. in Sudafrika, Sonderabdruck aus der Zeitschrift des Vereines deutscher Ingenieure, Jahrgang 1913, Seite 4

Hadley AE, “Power Supply on the Rand”, In: Journal of the Institution of Electrical Engineers (London), Vol 51, Mar 1913:2-17

Otley TG and Pickles V, Boiler House Operation and Maintenance with Special reference to the Rand Power Companies’ Plant, In: Journal of the South African Institution of Engineers, Jan 1917

Parsons RH, Development of the Parsons Steam Turbine, Constable & Co, London, 1936

Jacobs AM, The Development of Electrical Power Supply in the Union of South Africa, In: The Transactions of the S.A. Institute of Elecrical Engineers, Aug 1941

Verster, HA: Short History of Brakpan (1864-1952)

Fenwick W and Torr HM, Electric Power Supply to the Mining Industry in the Transvaal and Orange Free State: Its Generation, Transmission and Cost, In: Reprint from “The Seventh Commonwealth Mining and Metallurgical Congress”, 11 April 1961

Shorten, JR: The Johannesburg Saga. John Shorten (Pty) Ltd, Johannesburg, 1966

Troost Dr N and Norman HB, Electricity Supply in South Africa 1909-1969, in: The Transactions of the S.A. Institute of Electrical Engineers, Sept 1969

Smith, JX: Brakpan, Transvaal, South Africa. Courier-Gazette Publishers (Pty) Ltd, Johannesburg, 1970

Webster, S: The Brakpan Story, Simply the Best, South Africa, 1994

Conradie, SR and Messerschmidt, LJM: A Symphony of Power: The Eskom Story. Chris van Rensburg Publications (Pty) Ltd, Johannesburg, 2000

Information was also received from the Eskom Information Centre and the National Archives.