Peaking power stations

Vision: Accountable and cohesive leadership that ensures disciplined execution in a competitive environment.

Peaking Operating Unit Mandate: Optimally produce power and maintain the plant in order to consistently meet South Africa’s electricity demand during peak periods or when required.

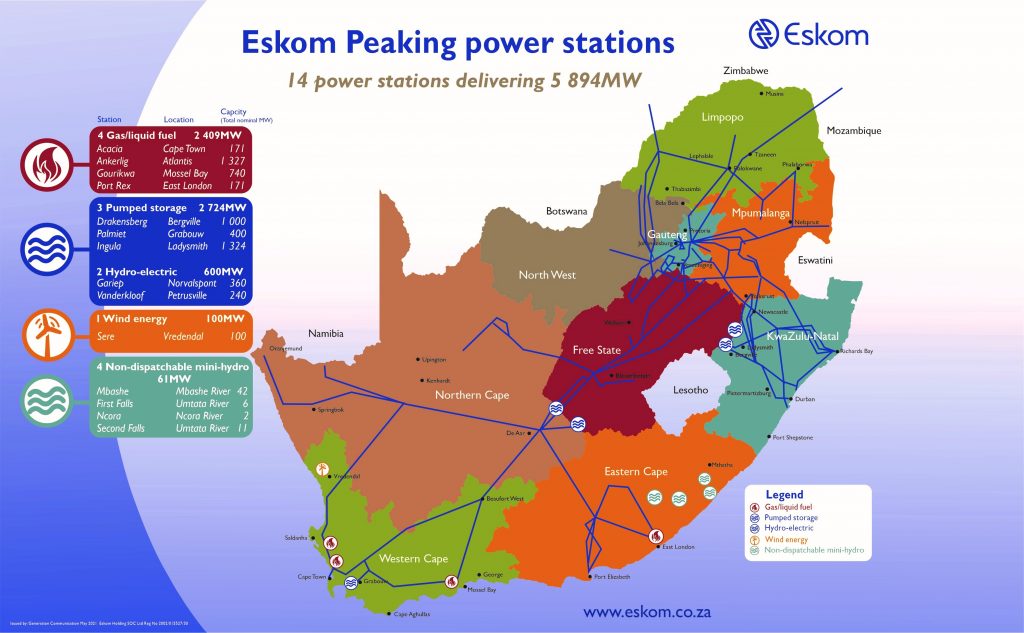

The term peaking means we can react quickly to changes in demand and provide power to supplement that generated by base-load stations, which are coal and nuclear. South Africa’s peaking power stations are hydroelectric, hydro pumped storage and gas turbine stations. Peaking Generation consist of stations that operate during peak periods or when the system is constrained, which is when demand is higher than what your base-load can supply at the time.

The term peak load indicates the additional demand placed on the system over and above the normal base load requirements. In South Africa, peak demand periods occur in the early mornings and early evenings between 5 and 9. The morning peak is a combination of industrial and domestic demand whereas the evening peak is mainly domestic. In winter, record evening peaks occur with the increased use of domestic heating appliances and in summer, air conditioning has the same effect.

There are fourteen peaking power stations: gas turbine stations, hydroelectric (run-of-river), hydro pumped storage and wind with a total nominal capacity of 5 894.4MW’s.

Peaking Generation has three visitors centres in the group:

Mandate: To enhance the reputation of Eskom by promoting a positive perception of the Generation Group and goodwill towards the Eskom brand.

The visitors centres are a platform to support Eskom in communicating our strategic messages.

Guided tours are conducted daily during weekdays for the general public, industry, business, NGO’s, clubs, and educational institutions. Contact us on the following:

- Drakensberg Visitors Centre (KwaZulu-Natal), Tel +27 36 438 2089 [email protected]

- Ingula Visitors Centre (KwaZulu-Natal), Tel +27 36 342 3236 [email protected]

- Palmiet Visitors Centre (Western Cape), Tel +27 21 859 2690 [email protected]

Acacia power station

Acacia consists of three 57 MW gas turbine generators, which are driven by engines similar to those of a Boeing 707 aircraft. They were commissioned in 1976.

Acacia provides back-up electrical supply to Koeberg Nuclear Power Station as per National Nuclear Regulator licensing requirement.

The station can be operated by remote control from Eskom’s National Control Centre at Simmerpan to provide back up and black-start capability.

Sequencing is automatic and the units are synchronised to the system approximately 190 seconds after initiation of the start signal. The units are then driven to full load in 5 minutes if the “normal” loading rate is selected or in approximately 15 to 20 seconds if the “fast” loading rate is selected. The peak load output can only be sustained for three hours.

The gas turbines run on kerosene and each unit consumes 5, 7 litre/second at a base load of 57MW. Fuel is pumped to the site from bulk storage tanks through pipelines.

Fact sheet GS 0001: PORT REX AND ACACIA GAS TURBINE STATIONS

Ankerlig power station

The name Ankerlig is derived from an Afrikaans expression “Om die anker te lig”, which is symbolic of a community that rises above the chains of poverty to experience growth and prosperity.

Construction of the first phase commenced in January 2006 and comprised of 4 x 148 MW units, which was completed and handed over for commercial operation by June 2007. The second phase comprising of 5 x 147MW units was declared commercial during February 2009. The total installed capacity is 1 327 MW.

The OCGT units are powered by Fuel oil (Diesel). They are intended to supply electricity into the National Grid during peak hours and emergency situations. In addition to their generating capabilities the units are also used to regulate network voltage fluctuations (SCO – Synchronous Condenser Operation)

As Ankerlig has no direct pipeline to a fuel depot, the fuel is brought in by road tanker and off-loaded at one of the off-loading skids at a rate of between 1 300 -1 400 litres/min.

Did you know facts:

- Built within a record time of 18 months

- Uses liquid fuel (diesel)

- Can operate in synchronous condenser operation (SCO) – regulating the fluctuations in the network voltage

- Similar technology that is used in the aviation industry, but designed for industrial use

- Ankerlig power station boasts the largest HV yard in Eskom

- Turbine is 9.45 m and 4.1 m in diameter

- Combustion chambers weigh approximately 6 tons each

- The generator weighs 223 tons and is the heaviest single component on site

- The exhaust stack is 30 m high and 10 m in diameter

- Maximum temperature of hot air released into the atmosphere is 560 degrees.

- Fuel to Ankerlig is delivered by tankers

- Fuel off- loading rate at Ankerlig is between 1 300 – 1 400 litres per minute

- Fuel storage tanks on site hosts 2.7 million litres of diesel

- Each unit uses 40 tons of diesel per hour

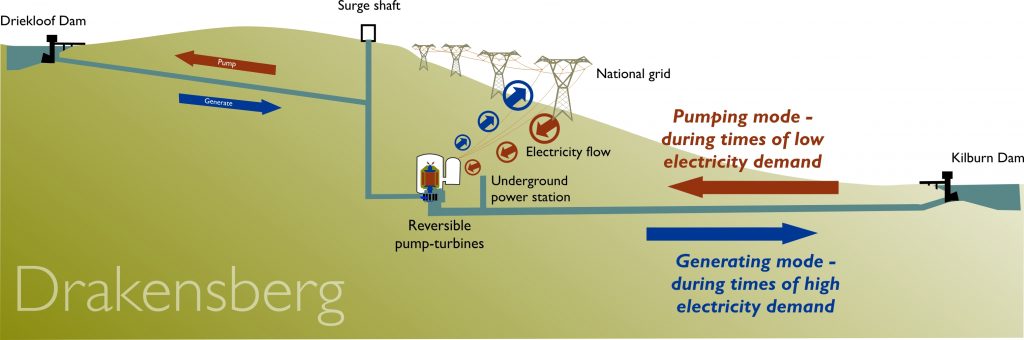

Drakensberg pumped storage scheme

Energy source: Water

The Drakensberg Pumped Storage Scheme is situated in the picturesque Northern Drakensberg of KwaZulu-Natal.

Protection and restoration of the environment continues to be a focus area and almost all installations are underground. The four reversible pump turbines, situated 156 metres below ground level, generate 1 000MW (4 x 250MW) of electricity for the Eskom National Grid during peak periods. The scheme is also a joint venture between Eskom and the Department of Water Affairs in the transfer of water from the Tugela River to the Vaal Dam via the Sterkfontein Dam in the Free State.

How to get there

The Visitors Centre is located off the R74 between the towns of Harrismith (Free State) and Bergville (Northern Berg of KwaZulu-Natal). The R74 can be accessed from the N3 between Johannesburg and Durban.

Contact details:

Email: [email protected]

Tel: +27 36 438 2088/9

GPS: S28o 35.142’; E29o 05.378’

Opening hours:

Monday to Thursday 08:00 – 16:00

Friday 08:00 – 12:00

Did you know facts:

- Recognised by the SAICE (South African Institute of Civil Engineers) as the most Outstanding Civil Engineering Achievement for 1981

- 150 metres below the surface – equivalent to a 50 storey building

- Only lift shaft buildings and transmission lines are visible on the surface

- Three huge underground caverns house the inlet valves, the generators and the 400 kV high voltage systems respectively

- Compartments containing SF6 gas insulate the underground high voltage conductors and equipment.

- The underground machine hall is a cavern 200 metres in length (as big as two soccer or rugby fields)

- The machine hall houses 4 x 250 MW generators/reversible pump turbines

- Can supply the National Grid with 1 000 MW in less than three minutes

- Has two 250 ton roof cranes linked with a lifting beam, which together, can lift 500 tons

- The generator weighs 430 tons

- It is a joint venture with Department of Water Affairs in the Tugela-Vaal Water Transfer scheme transferring water from the Tugela River in KwaZulu-Natal to the Vaal Dam in Gauteng

- Can generate continuously for 28 hours using the water stored in the upper dam

- 70 000 litres (70 tons) of water per second flow through the spherical valves, which have an internal diameter of 2,25 m

- 75 000 rock bolts were used to stabilise the rock in the underground caverns

- 1 330 000 tons of rock were excavated during construction and were used to build the dams and roads

- The steel shaft connecting the generator to the turbine is 1.1m in diameter and 18.5m in length

- The Drakensberg Visitors Centre receives over 13 000 visitors on tours through the power station each year and has received over 450 000 visitors since it opened its doors in 1984 to date.

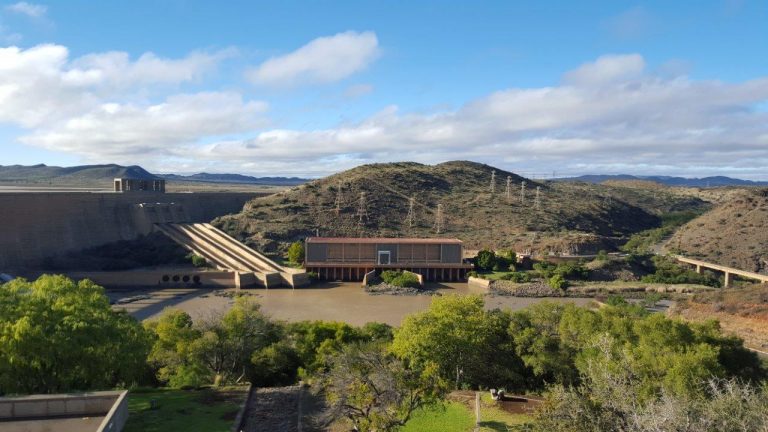

Gariep hydroelectric power station

Gariep and Vanderkloof Power Stations are situated on the border of the Eastern Cape and Free State; and the Northern Cape provinces respectively; and built adjacent to the Gariep and Vanderkloof Dams in the country’s summer rainfall region.

Their electricity feeds into the Eskom national grid to supply power for peak and emergency demand periods, as well as base load energy when excess water poses a flood risk.

The Gariep and Vanderkloof Dams, owned and operated by the Department of Water Affairs, are the largest and second largest water reservoirs in South Africa, with Vanderkloof 130 km downstream of Gariep Dam. They, together with the Eskom hydro power stations, are integral components of the Orange River Water Scheme.

There is close liaison and cooperation between DWA and Eskom on these projects. The partnership cooperation agreement ensures provision is made for irrigation, urban water supplies, recreation and electricity generation in a water-scarce South Africa, as the multi-purpose nature of the Orange River Scheme means balance has to be maintained between water resources for irrigation, for example, and power generation.

Gariep’s first two machines went into commercial service in 1971 and the last two in March 1976. The station was originally named after its political sponsor, Hendrik Verwoerd.

There is close liaison and cooperation between DWA and Eskom on these projects.

Did you know facts:

- Gariep Dam has a total storage capacity of approximately 5,340,000 megalitres (5,340 hm3).

- The dam crest is some 1300m sea level.

- Up to 220 000 litres (220 ton) of water per second flow through the penstock, which have an internal diameter of 7m

- The station houses four vertical ‘Francis’ generators with a capacity of 90 MW each – enough to power 70 000 households.

Fact Sheet:

Hy 0005 – ESKOM’S HYDROELECTRIC POWER STATIONS – GARIEP AND VANDERKLOOF

Gourikwa power station

The station was named after an indigenous tribe (Gourikwas) who occupied the land on which the station is build.

Construction of the first phase commenced in January 2006 and comprised of 3 x 148 MW units which was completed and handed over for commercial operation by June 2007. The second phase comprising of 2 x 148 MW units was declared commercial during November 2008. The total installed capacity is 740 MW.

The OCGT are powered by Fuel oil (Diesel). These units supply electricity into the National Grid during peak hours and emergency situations. In addition to their generating capabilities the units are also used to regulate network voltage fluctuations (SCO – Synchronous Condenser Operation).

Gourikwa has a 200 mm pipeline direct from PetroSA to the storage tanks. The length of the pipe is approximately 4.2 km long and can handle a pressure of 1 700 kPa to accommodate the design pressure from the PetroSA side. When the storage tanks on site need to be filled the fuel is pumped at a rate of 180 kl/hr which can, in rare circumstances, be pushed up to 200 kl/hr. As a backup, Gourikwa also has five off-loading skids that can off-load diesel from road tankers at a rate of 1 300 -1 400 l/min.

Did you know facts:

- Built within a record time of 18 months

- Uses liquid fuel (diesel)

- Can operate in synchronous condenser operation (SCO) – regulating the fluctuations in the network voltage

- Similar technology that is used in the aviation industry, but designed for industrial use

- Turbine is 9.45 m and 4.1 m in diameter

- Combustion chambers weigh approximately 6 tons each

- The generator weighs 223 tons and is the heaviest single component on site

- The exhaust stack is 30 m high and 10 m in diameter

- Maximum temperature of hot air released into the atmosphere is 560 degrees.

- Fuel to Gourikwa is delivered via a pipeline connected to PetroSA

- Fuel transfer rate to Gourikwa is 3 000 litres per minute

- Fuel storage tanks on site hosts 2.7 million litres of diesel

- Each unit uses 40 tons of diesel per hour

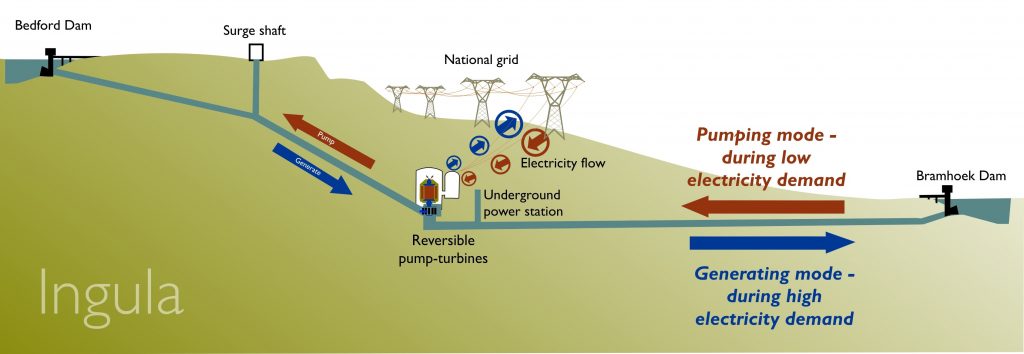

Ingula pumped storage scheme

Pre-requisites for a pumped storage scheme are:

- favorable geology,

- availability of water,

- and dam sites that are located relatively close together, but with a significant difference in altitude.

Eskom initiated a study to identify such sites for new pumped storage schemes in the 1980’s. Initially more than 90 potential sites were investigated, culminating in the short-listing of only three. The final selection was a site north-east of Van Reenen’s Pass, spanning the escarpment of the Little Drakensberg, and straddling the provincial boundary of the Free State and KwaZulu-Natal. This is also the continental watershed between the Vaal River catchment, flowing into the Atlantic Ocean, and the Thukela River catchment, flowing into the Indian Ocean.

Initially known as ‘Braamhoek’, the name was officially changed to ‘Ingula’ in March 2007. Ingula alludes to the creamy contents at the top of a milk calabash. The quest to find an appropriate name for Ingula Power Station was inspired by the mountains and foamy river-waters, and the rich cultural symbols and traditions of the indigenous people on both sides of the border.

The Ingula pumped storage scheme consists of an upper and a lower dam, each capable of holding approximately 22 million cubic metres of water. The dams, 4.6km apart, are connected by underground waterways passing through a subterranean powerhouse with four 333 MW generators.

To generate electricity during times of peak demand, water is released from the upper dam, passing through the pump/turbines, into the lower dam. During times of low energy demand, the pump/turbines are used to pump the water from the lower dam, back to the upper dam.

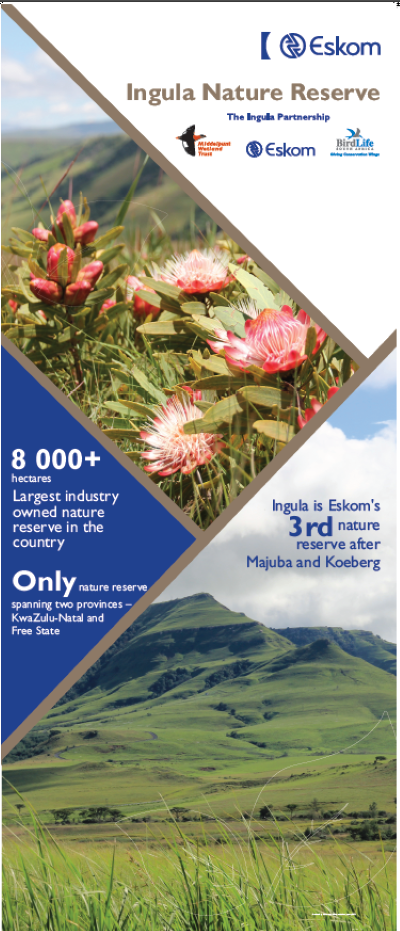

Eskom has taken a decision to manage the area surrounding the dams and construction sites as a conservation area. This area, located in both the Free State and KwaZulu-Natal, is of significant value as a source of water for the Highveld and serves as a habitat for a variety of plants, birds and animals.

To visit the Ingula Pumped Storage Scheme contact:

Ingula Visitors Centre (KwaZulu-Natal),

Tel +27 36 342 3236

[email protected]

Did you know facts:

- Ingula is the 14th largest pumped storage scheme in the world

- Total generating capacity – 1 332MW (4 x 333MW units)

- 16 hours of continuous generation

- Energy storage capacity: 16 hours (21 000 MWh) At peak flow, the equivalent volume of eight Olympic size swimming pools will pass through the turbines every minute.

- Main access tunnel is 1,4kms in length with a 1:10 gradient

- 6km and 441m: distance between upper and lower reservoirs

- 16km of tunnels constructed of which are 8km of waterways

- 11 500 000m3 of rock excavated from tunnels, waterways and powerhouse complex

- 15 000t of steel used in steel linings

- Largest man-made mudrock cavern in Africa 187mx26mx54m length, width and height

- Location of the power station is 116 storeys underground,

- The underground power station is at a level 115m below the entrance to the main access tunnel and 350m below the top of the mountain where the upper dam, Bedford is situated

- The machine hall has the world’s largest span underground cavern excavated in soft mud rock geology

- The quarry produced 2,6 million tons of aggregate

- The concrete works was reinforced by 3 600 tons of steel

- 450 000 cubic metres of concrete was used

- Over three kilometres of steel lining was manufactured on site, weighing 15 000 tons

- Over eighteen kilometres of welds were done on the steel linings, weighing ninety six tons

- Time spent on welding the steel linings was ninety-four thousand man-hours

- Seven hundred thousand welding rods were used for the steel linings

- Total reinforcing installed is 22 700 tons

- If all of the reinforcing bars were laid out end to end it would stretch for 7,6 million km – enough to circumnavigate the earth, at the equator, 189 times

- The difference in altitude between the upper and lower dam is 441 metres.

- Fossils from the Permian Period uncovered during construction are around 255 million years old, much older than the dinosaurs

- 1000ha of wetland protected

- 600+ha of alien vegetation eradicated

- 110+km of firebreaks prepared annually

- 100+km of historical erosion ditches being rehabilitated

- 335+ species of bird seen at Ingula

- 40+ species of mammal seen at Ingula

- 28+ species of reptile seen at Ingula

- Important Birding and Biodiversity Area (IBA) status held by the Chatsworth and Bedford wetlands at Ingula’s upper site

- Three endangered habitats (grassland, wetland and escarpment forest)

- Four critically endangered species (Wattled Crane, Bearded Vulture and White-winged Flufftail, White-backed Vulture)

- Biodiversity is protected at Ingula

- Mitigation measures implemented to minimise the impact of powerlines on birds

- The Ingula Partnership formed between Eskom, BirdLife South Africa and Middelpunt Wetland Trust since 2004

- The Ingula Partnership won the Stewardship category a the South African Wetlands Society Awards 2019

- The Ingula Nature Reserve 8000ha area property spanning KwaZulu-Natal and Free State provinces was declared a nature reserve 2018.

- 10 years to construct from 2006 to 2016

- Since the Ingula Visitors centre opened its’ doors in January 2009 – March 2020 (11 years) it has hosted 58 500.

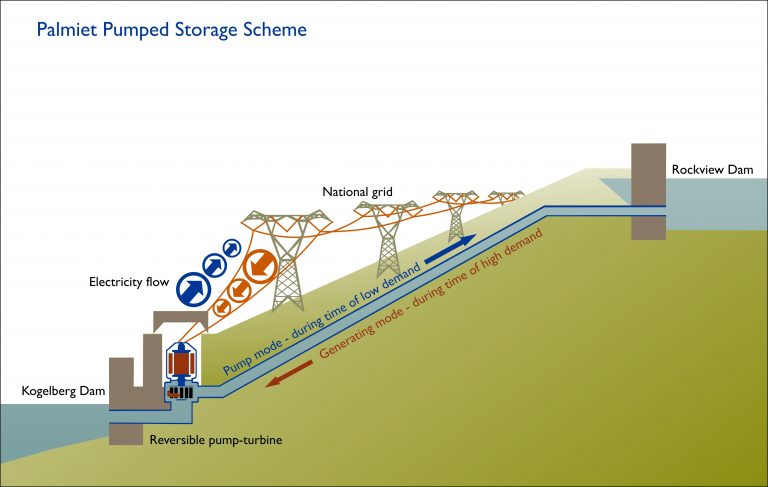

Palmiet pumped storage scheme

Palmiet consists of two 200MW units at an installed capacity of 400MW and was fully commissioned in 1988.

Palmiet Pumped Storage Scheme is part of a water transfer scheme. For generating purposes, water is released from the upper Rockview Dam to the two reversible pump turbines located 60 metres below ground level. The units are also used to pump additional water from the Palmiet River via the Rockview Dam to the Steenbras Dam to supplement the Cape Town water supply. The station can be operated by remote control from Eskom’s National Control Centre at Simmerpan, Germiston, Gauteng, the power station can respond rapidly to any changes in demand for electricity and supply power to the grid within two and half minutes.

Palmiet is located in an ecologically sensitive area, home to species of fynbos found nowhere else in the world except the south-western Cape. The whole Palmiet site is a conservation area and in December 1998 the area was declared a Biosphere Reserve by UNESCO – the first in South Africa.

To visit the Palmiet Pumped Storage Scheme contact:

Palmiet Visitors Centre (Western Cape), Tel +27 21 859 2690 [email protected]

Did you know facts:

- The two units are located underground at the base of 25 storey deep shafts.

- The vertical machines are the same height as a 5 storey building

- Water stored in the upper reservoir (Rockview Dam) is released into a waterway 6, 2 metres in diameter – large enough to accommodate a double-decker bus.

- Up to 180 tons of water a second pass through the main waterway to the two turbine sets – enough to fill an Olympic size swimming pool in a matter of seconds.

- During off peak periods, when the water is pumped back to the upper reservoir the machines use the equivalent of several small towns demand for electricity.

- Recognised by the SAICE (South African Institute of Civil Engineers) as the most Outstanding Civil Engineering Achievement for 1987

- 1988 EPPIC Award (Environmental Planning Professions Inter-disciplinary Committee) for integrated environmental planning and management

- 1997 Conserva Award from RSA Minister of Environmental Affairs/Tourism for sustainable use of the environment

- In 2003 won the prestigious Blue Planet Prize awarded by the IHA (International Hydropower Association) for excellence in technical, economic and environmental performance

- The Palmiet Visitors Centre operating from January 1991 to March 2020 (29 years) has had 168 565 visitors.

Port Rex power station

Port Rex has three 57 MW gas turbine generators, which are driven by engines similar to those of a Boeing 707 aircraft. They were commissioned in 1976.

Despite the station being so small, Port Rex is critical for system voltage stability in the Eastern Cape, due to its location at the end of a long transmission line. Long transmission lines have the effect of causing phase changes between the voltage and the current being transported, hence the longer the lines, the more voltage instability occurs. Port Rex has the capability of regulating this voltage instability via an operating mode called synchronous condenser operation.

The units can be started by means of a signal from either the local or remote control centre.

Sequencing is automatic and the units are synchronised to the system approximately 190 seconds after initiation of the start signal. The units are then driven to full load in 5 minutes if the “normal” loading rate is selected or in approximately 15 to 20 seconds if the “fast” loading rate is selected.

The gas turbines run on kerosene and each unit consumes 5, 7 litre/second at a base load of 57MW.

Fuel is pumped to the site from bulk storage tanks through pipelines.

Fact sheet

Sere wind farm

South Africa’s Western Cape is blessed with abundant wind energy resources. The Sere Wind Farm is situated on the Atlantic coast, near the towns of Koekenaap, Lutzville and Vredendal.

The Sere wind farm takes its name from the Nama word meaning ‘cool breeze’. It consists of 46 wind turbines, each with a capacity to produce 2.3 MW. Full commercial operation of the project was achieved at the end of March 2015. Sere is Eskom’s first large-scale renewable energy project and demonstrates the utility’s commitment to reducing its carbon footprint and to investing in a sustainable energy future.

Fact Sheet:

Vanderkloof power station

Gariep and Vanderkloof Power Stations are situated on the border of the Eastern Cape and Free State; and the Northern Cape provinces respectively; and built adjacent to the Gariep and Vanderkloof Dams in the country’s summer rainfall region. Their electricity feeds into the Eskom national grid to supply power for peak and emergency demand periods, as well as base load energy when excess water poses a flood risk.

The Gariep and Vanderkloof Dams, owned and operated by the Department of Water Affairs, are the largest and second largest water reservoirs in South Africa, with Vanderkloof 130 km downstream of Gariep Dam. They, together with the Eskom hydro power stations, are integral components of the Orange River Water Scheme.

There is close liaison and cooperation between DWA and Eskom on these projects. The partnership cooperation agreement ensures provision is made for irrigation, urban water supplies, recreation and electricity generation in a water-scarce South Africa, as the multi-purpose nature of the Orange River Scheme means balance has to be maintained between water resources for irrigation, for example, and power generation.

The two units at Vanderkloof were put into commercial service in January and March 1977 respectively.

Fact Sheet:

Hy 0005 – ESKOM’S HYDROELECTRIC POWER STATIONS – GARIEP AND VANDERKLOOF

Did you know facts:

- The hydroelectric power station at the Vanderkloof Dam was the first power-generation station in South Africa situated entirely underground.

- The Station has two vertical ‘Francis’ generators with a capacity of 120MW each and can be on load within 3 minutes.

- Up to 220 000 litres (220 ton) of water per second flow through the penstock, which have an internal diameter of 7m

- The Vanderkloof Dam is situated approximately 130km downstream from Gariep Dam and is fed by the Orange River, South Africa’s largest river.

- The river has a total length of 2,200km.

- Vanderkloof Dam is the second-largest dam in South Africa (in volume), having the highest dam wall in the country at 108 metres.

- The dam was commissioned in 1977; it has a capacity of 3,187.557 million cubic metres and a surface area of 133.43 square kilometres when full.

- Irrigation in the vast area downstream of the Vanderkloof Dam, which has turned thousands of hectares of arid veld into highly productive agricultural land, was made possible by the construction of the Vanderkloof Dam.

- Vanderkloof Dam was originally scheduled to commence at the same time as the Gariep Dam, but in October 1967, construction was postponed in accordance with government measures to curb inflation in the national economy. During 1969, the Cabinet decided to proceed with the project and in 1970 tenders were requested for a second time. The tender prices received, were much higher than expected with the result that Cabinet decided that the Department of Water Affairs should construct the dam using their own construction staff and equipment.

- The dam is a composite gravity arch dam containing 1.1 million m3 of concrete.

- The 6 200ha Rolfontein Nature Reserve is located on the north western shore of the dam

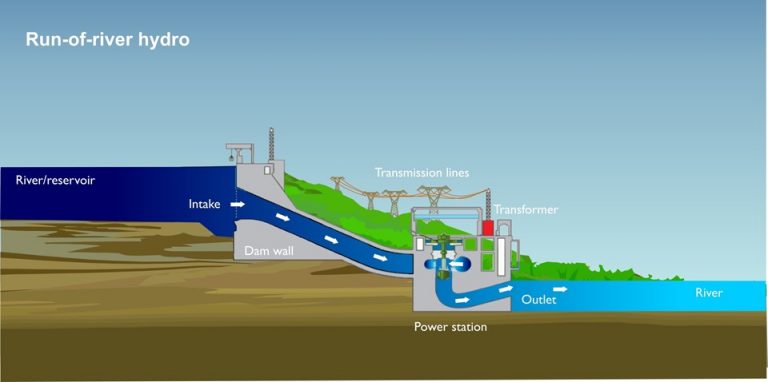

Non-Dispatchable Hydros

These hydroelectric power stations are situated in the former Transkei and Ciskei. While primarily peaking stations, they also operate as base load when water is available. These non-dispatchable power stations generate electricity but cannot be turned on or off in order to meet societies fluctuating electricity needs.

First Falls 6MW

This is a run-of-river hydroelectric power station on the Umtata River, commissioned in 1979. It has two 3 MW units.

Second Falls 11MW

Downstream of First Falls, Second Falls is also a run-of-river hydroelectric scheme with two 5,5 MW units commissioned in 1979. During the dry season the flow to the two stations is augmented by releases from Umtata Dam, situated some 5km north –west of Umtata in the Eastern Cape.

Mbashe 42MW

This run-of-river hydroelectric station on the Mbashe River in the Eastern Cape has three 14 MW machines commissioned in 1985. Make up water for this station is released from the Ncora Dam via the small Ncora hydro station.

Ncora 2.4MW

This small hydro station in the Ncora River has three units with a total installed capacity 2 MW and was commissioned in 1983.